Buy Direct

from the Manufacturer

Sell our Products

Become a Distributor

Discounts

on volume purchases

Visit Us

at our Miami office

from the Manufacturer

Become a Distributor

on volume purchases

at our Miami office

An industrial generator is a heavy-duty power system designed to provide reliable electricity during outages or in locations without grid access. These robust machines differ from residential units by offering higher power outputs, longer runtime capabilities, and advanced monitoring features essential for critical operations.

Key Industrial Generator Facts:

– Power Range: 10 kW to 5,320 kW (Caterpillar offers the largest range globally)

– Fuel Types: Diesel, natural gas, propane, and bi-fuel options

– Applications: Manufacturing plants, hospitals, data centers, mining operations, construction sites

– Runtime: Designed for continuous operation vs. residential units built for occasional use

– Features: Three-phase power output, automatic transfer switches, remote monitoring capabilities

When power goes out at an industrial facility – whether it’s a telecommunications center, manufacturing plant, or hospital – the consequences can be devastating. Modern businesses simply can’t afford extended downtime. That’s why companies like Caterpillar test every generator set “at and above 100% of rated load” before delivery, ensuring reliability when it matters most.

Industrial generators serve as the backbone of business continuity. They protect critical processes, prevent data loss, maintain safety systems, and keep operations running smoothly during grid failures. From 20 kW portable units that can ship within 24-48 hours to massive 2,000+ kW stationary systems, these machines are engineered for the demanding requirements of commercial and industrial environments.

Key industrial generator vocabulary:

– smart energy management

– smart power management

Think of an industrial generator as the heavy-duty workhorse of the power generation world. While your home generator might be like a reliable sedan, industrial generators are more like massive freight trains – built to carry enormous loads over long distances without breaking a sweat.

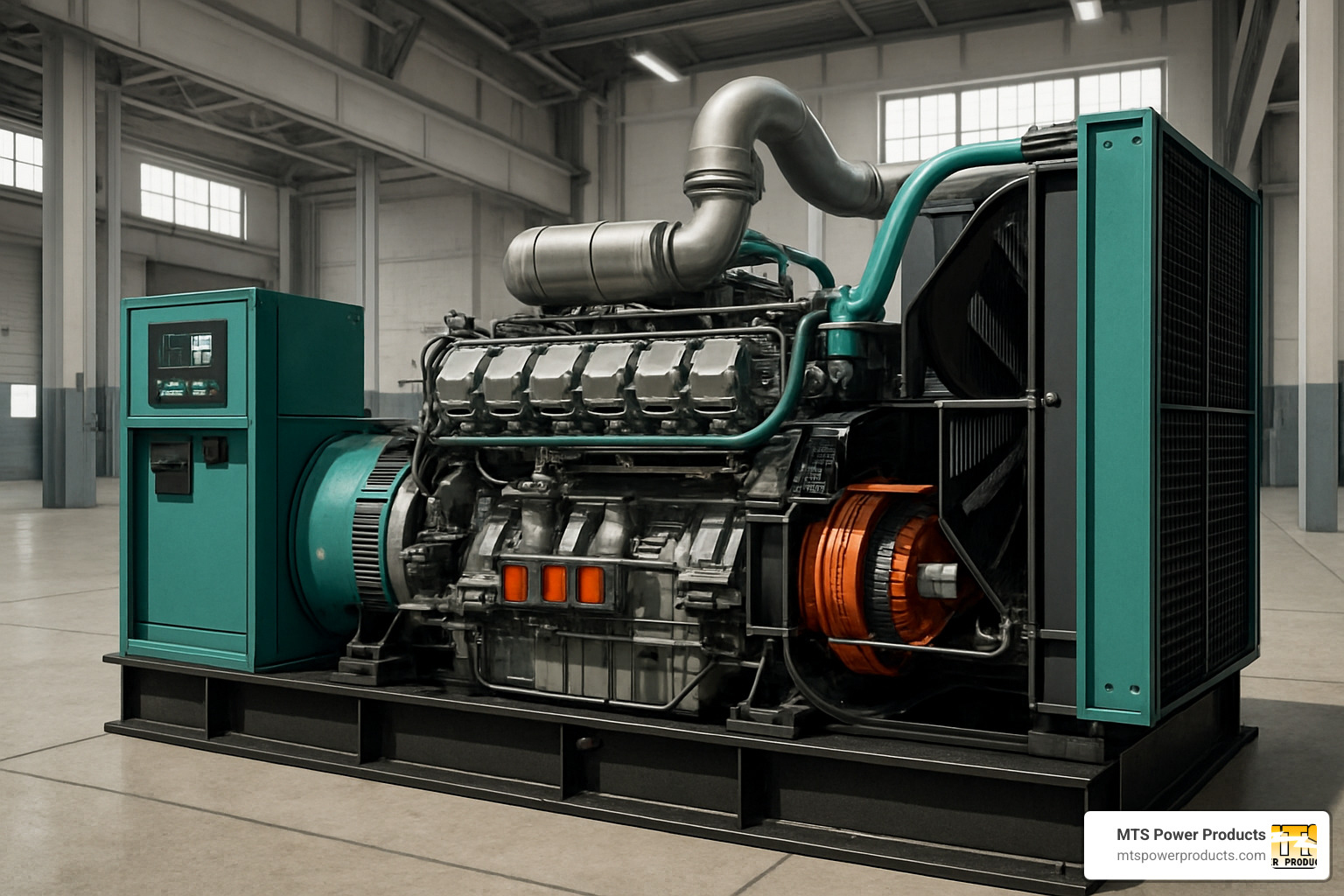

These sophisticated machines work by converting mechanical energy into electrical power through a carefully orchestrated dance between an engine and alternator. The engine provides the muscle, spinning the alternator which transforms that rotational force into the electricity that keeps factories humming, hospitals running, and data centers operational.

What makes industrial generators truly impressive is their continuous-duty rating. Unlike portable units designed for occasional use, these powerhouses can run 24/7 for months at a time. They’re engineered with commercial-grade components that handle harsh environments – whether that’s a dusty construction site or a humid industrial facility in South Florida.

The voltage ranges available span from standard 208V up to 13,800V for specialized applications. Most industrial units deliver three-phase output, which is essential for running large motors efficiently and keeping industrial machinery happy.

Durability is where industrial generators really shine. These machines use heavy-duty engines with reinforced components that can handle constant vibration and stress. Their cooling systems are oversized to prevent overheating during extended runs.

Long runtimes are perhaps the most significant difference. While your home generator might provide 8-12 hours of backup power, industrial units can run continuously for thousands of hours with proper maintenance.

Three-phase output is standard on industrial generators, crucial for powering large motors and industrial equipment efficiently. This type of power delivery is smoother and more efficient than single-phase power.

Advanced monitoring capabilities include sophisticated control panels with programmable displays, remote monitoring capabilities, and automatic safety shutdowns. At MTS Power Products, our McPherson Controls line takes this further with advanced features like remote monitoring and improved safety standards.

The engine serves as the heart of the system, typically a robust diesel or natural gas powerplant designed for continuous duty. These feature multiple cylinders, turbocharging, and sophisticated fuel injection systems optimized for efficiency and emissions control.

The alternator converts the engine’s mechanical rotation into electrical energy. Industrial alternators use heavy-duty windings and advanced engineering to handle varying loads without compromising power quality.

An Automatic Voltage Regulator (AVR) maintains consistent voltage output regardless of how the electrical load changes, ensuring your sensitive equipment receives stable power.

The control panel serves as the brain of the operation, monitoring all systems and providing the user interface. Modern panels include digital displays, comprehensive alarm systems, and communication ports for remote monitoring.

The cooling and exhaust systems prevent overheating during marathon operating sessions, using radiator cooling systems with thermostatic controls sized for continuous operation.

Finally, the fuel train ensures clean fuel delivery under all operating conditions, including fuel pumps, multiple filtration stages, and often fuel heating systems for reliable cold weather operation.

The industrial generator landscape offers something for every power need, from compact portable units to massive stationary powerhouses. Think of it like choosing the right vehicle – you wouldn’t use a sports car to haul construction materials.

Diesel generator sets are the reliable workhorses of industrial power, offering excellent fuel efficiency, impressive runtime capabilities, and proven reliability that keeps facilities running for weeks at a time. These units excel in remote locations where fuel delivery might be challenging.

Natural gas generators take a cleaner approach to power generation. By connecting directly to natural gas pipelines, they eliminate the headache of fuel storage while producing fewer emissions. It’s a win-win for urban installations where environmental regulations are strict.

Bi-fuel hybrid systems offer the best of both worlds – they automatically switch between diesel and natural gas, ensuring continuous operation even if one fuel source becomes unavailable.

Portable skid-mounted units bring power where you need it, when you need it. These mobile powerhouses are perfect for construction sites, emergency response, and temporary power applications where flexibility matters most.

Stationary containerized systems provide permanent backup power with weather-resistant protection built right in. Think of them as your facility’s power insurance policy – always ready, always protected.

Modern applications extend beyond traditional backup power into microgrid configurations, where generators work alongside renewable energy sources and battery storage.

Our Industrial Diesel Power Generators represent decades of engineering expertise, designed specifically for the most demanding industrial applications.

Choosing between fuel types isn’t just about cost – it’s about matching the right technology to your specific needs and operating environment.

| Aspect | Diesel | Natural Gas | Bi-Fuel |

|---|---|---|---|

| Fuel Cost | Moderate, subject to oil prices | Generally lower, stable pricing | Flexible based on available fuel |

| Efficiency | High (35-45%) | Good (30-40%) | Optimized for each fuel type |

| Emissions | Higher NOx and particulates | Lower overall emissions | Best of both worlds |

| Response Time | Immediate | Immediate | Immediate on either fuel |

| Fuel Storage | On-site tanks required | Pipeline connection preferred | Diesel storage + gas connection |

| Maintenance | Standard intervals | Slightly more frequent | Moderate complexity |

Diesel generators shine brightest in challenging environments where reliability trumps everything else. They’re the go-to choice for remote mining operations, offshore platforms, and emergency services where fuel availability might be uncertain.

Natural gas generators excel in urban environments where clean emissions matter and gas infrastructure is robust. They’re particularly popular with hospitals, data centers, and manufacturing facilities that value the unlimited fuel supply and cleaner burning characteristics.

Bi-fuel systems represent the cutting edge of generator technology, offering flexibility and reliability. They’re increasingly popular in mission-critical applications where fuel security is paramount.

Manufacturing facilities demand rock-solid power for production equipment, often dealing with massive motor starting loads that can temporarily spike power demand by 300-400%. Manufacturing uptime directly translates to profitability.

Healthcare facilities operate under life-and-death pressure where power interruption isn’t just inconvenient – it’s potentially fatal. A 200-bed hospital typically requires 1-2 MW of backup power to maintain critical care equipment. Healthcare life-safety loads include everything from ventilators to surgical lighting.

Data centers represent the ultimate in power-critical operations. Even a brief power hiccup can cost millions in lost data and service interruptions. These facilities typically employ multiple generators in parallel configurations.

Telecommunications infrastructure keeps our connected world running 24/7. Cell towers and switching centers require constant power availability, often in remote locations. Remote oil and gas operations face similar challenges, requiring reliable power where the nearest utility connection might be hundreds of miles away.

Agricultural operations have evolved into high-tech enterprises dependent on continuous power. Modern dairy farms need reliable power for milking systems, ventilation, and refrigeration.

Construction sites and event and rental power applications demand portable solutions that can deliver reliable power in temporary installations.

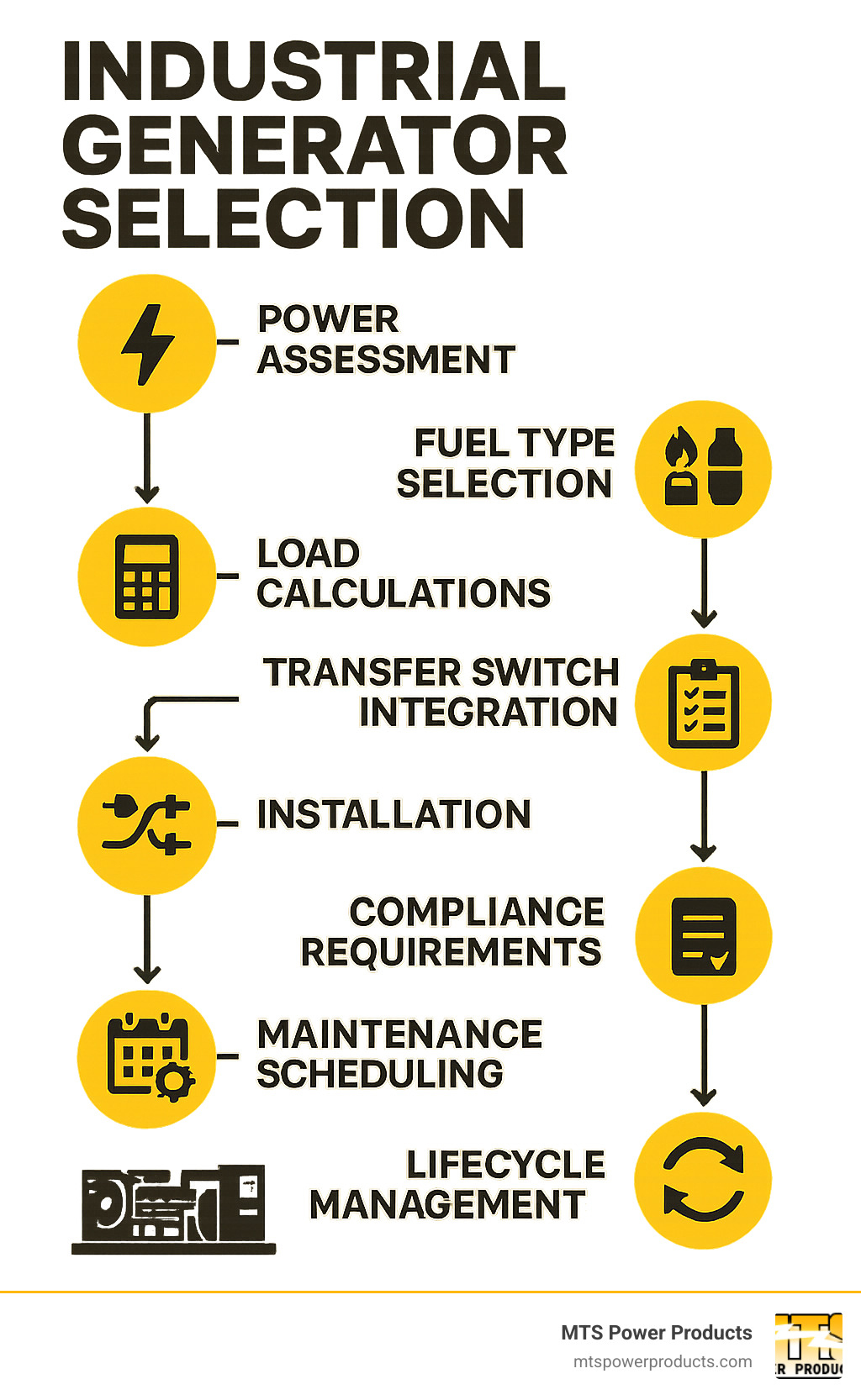

Choosing the right industrial generator is like buying a custom suit – one size definitely doesn’t fit all. Get it wrong, and you’ll either be left in the dark when you need power most, or you’ll be paying for capacity you’ll never use.

The secret to proper generator sizing starts with understanding your actual power needs through thorough load calculation. Environmental factors like altitude and temperature derating can significantly impact performance, so factor these into your calculations.

Smart facilities also plan for redundancy using N+1 configurations – having one more generator than you actually need for normal operation.

Our Industrial Generator Controller systems make integration straightforward by providing sophisticated monitoring and control capabilities that modern industrial facilities require.

Start with a comprehensive site power audit. Walk through your facility and list every piece of equipment that must keep running during an outage. Pay special attention to motor starting inrush currents, which can be three to six times higher than normal running loads.

Separate your critical loads from non-critical loads. Your production line might be critical, but the break room coffee maker probably isn’t. This simple step can save thousands of dollars by avoiding oversized generators.

Calculate your peak demand by adding up all critical loads, including that largest motor starting requirement. This gives you the absolute minimum generator capacity needed.

Smart planning means adding a 25% future expansion margin. It’s much cheaper to buy a slightly larger generator now than to replace an undersized unit in three years.

Finally, apply the 50-80% load rule. Most facilities operate at 50-80% of their calculated maximum load during normal conditions. This sweet spot provides optimal fuel efficiency while leaving room for unexpected load additions.

The best industrial generator in the world is useless if it can’t work seamlessly with your existing electrical system. Integration is where the magic happens – or where things go terribly wrong if not done properly.

Automatic transfer switches (ATS) are the unsung heroes of generator systems. These sophisticated devices constantly monitor your utility power and can switch to generator power in seconds when needed. Modern ATS units include load management features that can shed non-critical loads automatically if needed.

Switchgear coordination ensures all your electrical protection systems work together harmoniously. The generator’s protection settings must coordinate with your facility’s existing protection to prevent nuisance trips.

Soft loading systems gradually apply electrical load to large generators rather than hitting them with full demand immediately. Think of it like warming up your car on a cold morning.

For larger installations, paralleling gear allows multiple generators to work together, providing both redundancy and scalability. This setup enables true N+1 redundancy.

Modern facilities are increasingly combining generators with battery energy storage systems for optimized efficiency and lightning-fast response to load changes.

Think of your industrial generator as the guardian of your business continuity. Like any guardian, it needs proper care and attention to be ready when you need it most. The difference between a generator that starts reliably during an emergency and one that leaves you in the dark often comes down to consistent maintenance and smart compliance planning.

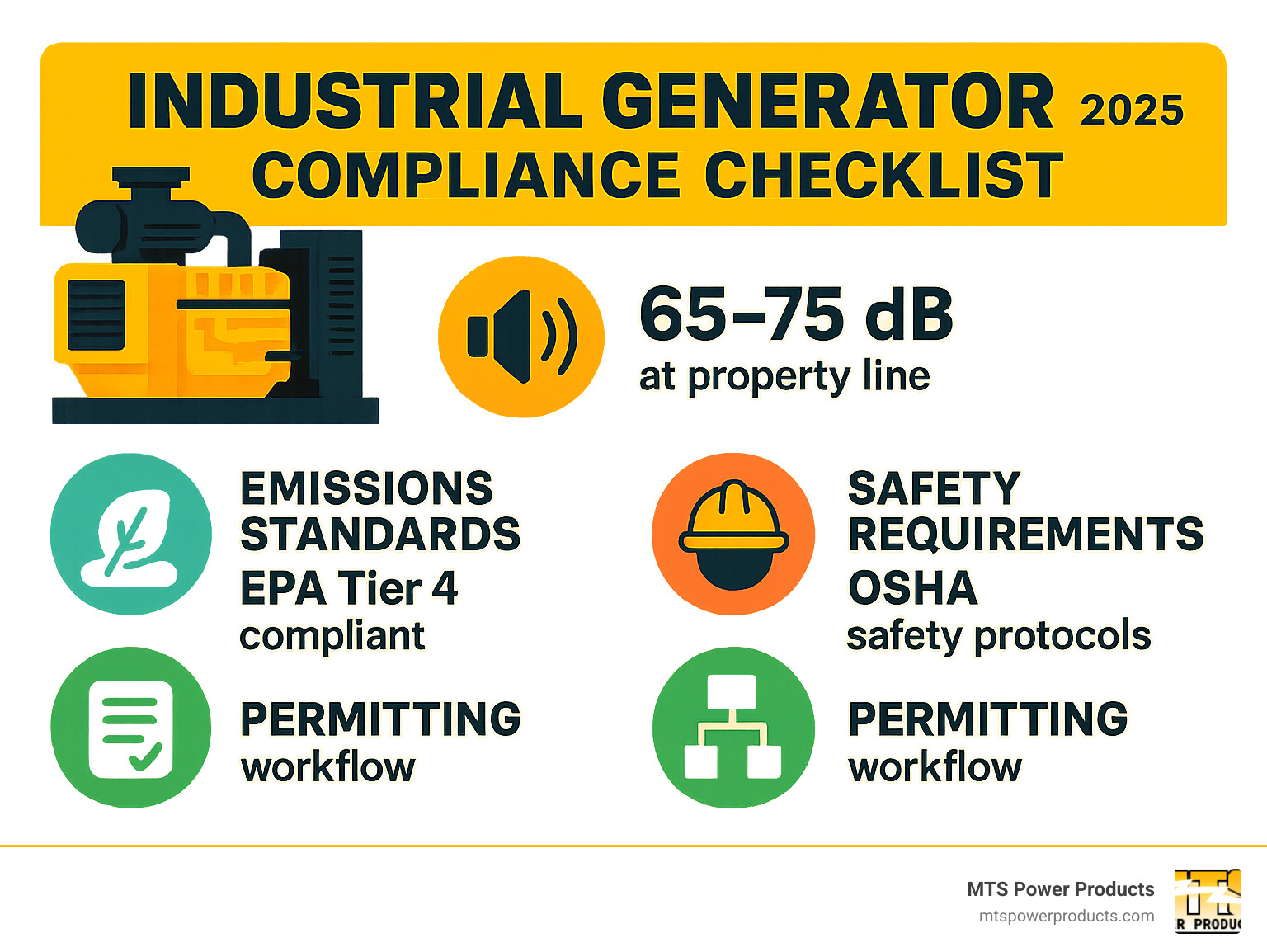

Modern industrial generators face a complex web of regulations. EPA Tier 4 Final and EU Stage V emissions standards require sophisticated after-treatment systems like selective catalytic reduction (SCR) and diesel particulate filters. These precision systems need specific maintenance procedures and high-quality diesel fuel to work properly.

Sound regulations add another layer of complexity. OSHA workplace noise limits and local noise ordinances mean your generator needs to be a good neighbor too. Acoustic enclosures can reduce noise levels by 10-20 decibels, often making the difference between compliance and costly violations.

At MTS Power Products, our Industrial Generators 2022 models come equipped with the latest emissions control technology and sound attenuation features.

Businesses that follow structured maintenance schedules rarely experience surprise generator failures. Those that treat maintenance as optional call us in panic during storms.

Daily walk-around inspections take just five minutes but prevent major headaches. Check for fluid leaks, listen for unusual noises, verify proper fluid levels, and look for any obvious damage.

Weekly exercise runs keep your generator’s systems active and alert you to developing problems. Run the unit under light load for 30 minutes – just enough to circulate fluids, charge the battery, and verify that everything starts properly.

Monthly service gets more detailed. Check battery condition and connections, clean or replace air filters, inspect belts and hoses for wear, and test the automatic start system.

Semi-annual major service is your generator’s equivalent of a comprehensive physical exam. Change oil and filters, inspect the cooling system thoroughly, test all safety shutdown systems, and perform load bank testing. Load bank testing is crucial – it’s the only way to verify your generator can actually handle its full rated load when an emergency strikes.

Annual comprehensive service involves inspecting internal engine components, testing alternator windings, and calibrating control systems. This deeper inspection identifies wear items that need replacement and ensures reliable performance for years to come.

Digital maintenance logs are becoming essential tools. They track service intervals automatically, monitor parts usage, and identify performance trends before they become problems.

Compliance isn’t just about avoiding fines – it’s about being a responsible business neighbor and protecting your investment from regulatory changes.

Noise compliance varies by location, but most jurisdictions limit generator noise to 65-75 decibels at property lines. Large diesel generators can produce 85-95 decibels without proper sound control. Sound-attenuated enclosures don’t just reduce noise – they protect your generator from weather while keeping your neighbors happy.

Emissions standards are getting stricter every year. New generators must meet EPA Tier 4 Final standards, which require advanced after-treatment systems. These systems work well when properly maintained, but they demand high-quality diesel fuel and regular service. According to the EPA’s regulations on stationary engines, natural gas generators typically produce lower overall emissions, though they may have different permitting requirements.

Safety regulations cover everything from proper ventilation to spill containment. OSHA requires emergency stop switches, low oil pressure shutdowns, and high temperature protection on industrial generators. Fuel systems need secondary containment to prevent environmental contamination.

Permitting can be the most time-consuming part of generator installation. Most installations require permits from local authorities, involving noise studies, emissions calculations, and safety plan reviews. Start this process early – we’ve seen projects delayed for months because permitting was treated as an afterthought.

The bottom line? Proper maintenance and compliance planning aren’t expenses – they’re insurance policies that protect your business when you need backup power most.

When you’re considering an industrial generator for your facility, you probably have plenty of questions. We’ve been helping businesses in Miami and around the world find the right power solutions for years, so we know what keeps facility managers up at night.

Getting the size right is crucial – too small and you’ll be left in the dark, too large and you’re throwing money away. The good news is that sizing an industrial generator follows a logical process.

Start by making a list of everything that absolutely must keep running during a power outage. Don’t forget that motors need extra power to start up, typically 3-6 times their normal running current.

Have your electrician check the amperage and voltage of your main electrical panel. Use an amperage-to-kW calculator to convert this to generator requirements, then add 25% for future growth.

Most facilities find they need generators sized for 50-80% of their total calculated load because not everything runs at the same time. A small manufacturing plant might need 200-300 kW, while a hospital could require 1-2 MW depending on its size and services.

Think of your generator like a reliable employee – treat it well, and it’ll be there when you need it most.

Daily checks should become second nature. Walk around the unit, look for leaks, listen for unusual sounds, and check fluid levels.

Weekly exercise runs keep everything moving. Start the generator and run it under light load for at least 30 minutes.

Monthly maintenance gets more detailed. Test the battery, inspect air filters, check belts and hoses, and make sure the automatic start system works properly.

Every 250 hours or 6 months, it’s time for oil changes, filter replacements, and cooling system checks.

Annual comprehensive service includes load bank testing, which is the only way to know if your generator can actually handle its rated load when needed.

Absolutely, but you need to be smart about it. A well-maintained used industrial generator can save you significant money while still providing reliable backup power.

Operating hours matter more than age for industrial generators. Look for diesel units with fewer than 5,000 hours or natural gas units with fewer than 3,000 hours.

Maintenance records tell the real story. Complete service history shows the previous owner cared about the equipment. If someone can’t provide maintenance documentation, walk away.

Insist on a load bank test before you buy. This puts the generator through its paces at full rated capacity.

During your visual inspection, look for obvious red flags like oil leaks, corrosion, worn belts, or jury-rigged repairs. Pay special attention to the cooling system and electrical connections.

For high-value purchases, consider hiring a qualified technician to inspect the unit. At MTS Power Products, we’ve seen customers save thousands by catching problems during the inspection phase rather than after delivery.

When the lights go out at your facility, what happens next? That moment reveals whether you’ve truly prepared for business continuity or simply hoped for the best. An industrial generator isn’t just another piece of equipment – it’s your lifeline when everything else fails.

A single power outage can shut down a manufacturing line, compromise patient care at a hospital, or crash critical data systems. The cost of downtime often exceeds the investment in backup power within hours. That’s why smart businesses don’t wait for disaster to strike – they prepare.

The right generator solution depends on understanding your unique needs. A textile manufacturer needs different power characteristics than a data center. A remote mining operation has different fuel requirements than an urban hospital. Every industrial power application tells its own story, and the solution must match that story perfectly.

At MTS Power Products, we’ve learned that one size definitely doesn’t fit all. That’s exactly why we focus on customized solutions rather than cookie-cutter approaches. Our Industrial Generators for Sale represent decades of engineering experience, but more importantly, they represent our commitment to keeping your operations running.

What makes us different? We’re not just selling generators – we’re solving power problems. Our proprietary McPherson Controls line brings programmable displays and improved safety features that you won’t find elsewhere. When you need remote monitoring or specialized control functions, we build them right into the system.

Being located in Miami gives us a unique advantage. We’re minutes from Miami International Airport and the Port of Miami, which means your generator can ship anywhere in the world quickly. Whether you need emergency power in South Florida or a custom solution for an overseas project, we’re positioned to deliver.

Here’s the truth about power outages: they’re not a matter of if, but when. The businesses that thrive are the ones that plan ahead. They invest in reliable backup power before they need it, not after they’ve already suffered losses.

Your operations deserve better than crossed fingers and hope. They deserve the peace of mind that comes from knowing your power will stay on when everyone else’s goes out. That’s the confidence that comes from partnering with a company that understands both the technology and the stakes involved.

Ready to protect your business from the next power outage? Let’s talk about building a resilient power strategy that keeps your operations running no matter what the grid throws at you. Because when it comes to industrial power, there’s no such thing as a small failure – only smart preparation.