Buy Direct

from the Manufacturer

Sell our Products

Become a Distributor

Discounts

on volume purchases

Visit Us

at our Miami office

from the Manufacturer

Become a Distributor

on volume purchases

at our Miami office

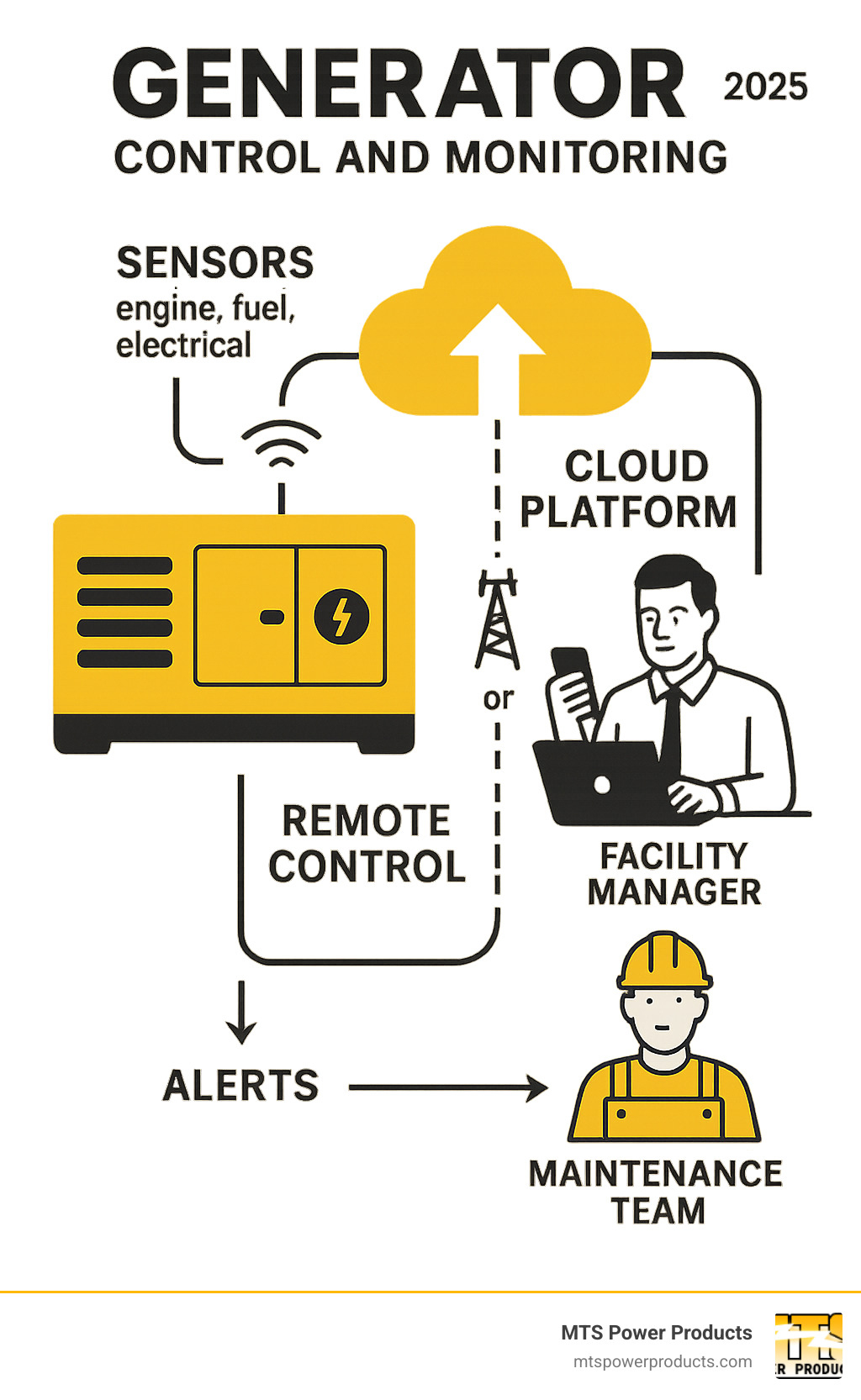

Generator control and monitoring systems are the digital nervous system of your power infrastructure, providing real-time oversight and automated management of your backup power equipment. These systems combine hardware controllers, communication devices, and software platforms to deliver 24/7 visibility into your generator’s performance, health, and operational status.

Key Components and Functions:

Whether you’re managing a single residential backup generator or overseeing multiple industrial units across different locations, these systems transform how you interact with your power equipment.

The stakes are high. During a power outage, it’s vital that your emergency power system works every time. A failed generator during a hurricane in South Florida or a manufacturing plant shutdown can mean thousands in lost revenue, compromised safety, and frustrated customers.

Modern generator control and monitoring systems solve this challenge by shifting you from reactive maintenance to proactive management. Instead of finding problems during an outage, you get advance warning. Instead of manual site visits, you monitor remotely. Instead of guessing when maintenance is due, you receive data-driven recommendations.

The technology has evolved dramatically. Today’s systems can prevent up to 95% of generator failures through early detection and alerts. Real-time updates arrive in less than 5 seconds, and monitoring devices automatically check system status every 15 minutes when no alarms are present.

Easy generator control and monitoring glossary:

When the grid drops, your generator becomes the heartbeat of your facility. Centralizing generator control and monitoring lets you see—and solve—problems before they stop that heartbeat.

Facilities that adopt remote monitoring typically prevent up to 95 % of avoidable failures and cut unplanned service calls by 25–35 % in the first year. Data-driven maintenance means fewer emergency visits, smarter parts replacement, and lower fuel costs.

Our Commercial Generator Controllers were engineered for exactly this purpose. They collect the data, issue real-time alerts, and integrate seamlessly with cloud dashboards so you always know the health of your power system.

• Instant alerts (< 5 s) for low fuel, high temperature, or weak batteries

• Trend analysis that spots small shifts—like a slow rise in coolant temperature—weeks before a shutdown

• Automated reports that document exercises, run hours, and compliance tests so nothing falls through the cracks

• Condition-based maintenance can trim service expenses 30–50 %

• Fewer routine site visits—technicians go only when data shows a real need

• Better fuel management and fewer catastrophic failures, thanks to integrated Generator Voltage Control Systems

A reliable monitoring setup is built on three pillars: the controller, the communication link, and the software that turns numbers into insight.

Your Generator Controller supervises every critical parameter—oil pressure, temperature, battery voltage, fuel level, voltage, current, and frequency—then logs it for later analysis. MTS controllers include programmable logic, on-board data storage, and bright, user-friendly displays.

Whether you choose LTE cellular, Ethernet, Wi-Fi, or satellite, the modem and antenna create a secure path between the generator and the cloud. Our hardware is hurricane-tested for South Florida conditions.

Cloud dashboards and mobile apps let you check status, run reports, or start and stop the generator from anywhere. Expansion I/O adds door switches, extra fuel sensors, or even ATS Controllers without rewiring the whole system.

Reactive maintenance means finding a dead battery only after the lights go out. Proactive maintenance, powered by continuous monitoring, flips that script.

• Predictive alerts flag rising engine temps or declining battery capacity early

• Usage-based scheduling replaces fixed-hour oil changes, saving time and supplies

• Historical trend charts reveal efficiency losses before they become costly

Secure remote access lets you start, stop, reset alarms, or tweak set-points without a site visit. Technicians arrive knowing the exact fault code and required parts, cutting mean-time-to-repair dramatically.

Hospitals, data centers, and production lines need more than simple start/stop. They need orchestrated control across multiple generators, loads, and the utility grid.

• Automatic synchronizing brings sets online in seconds

• Intelligent load demand starts or stops units to match real-time kW

• Peak-lopping and import/export modes cut demand charges

• Soft-load transfer keeps sensitive equipment happy

Automatic Transfer Switches from MTS ensure seamless transitions.

Integrated relays guard against over/under voltage (27/59), frequency drift (81 O/U), reverse power (32), overcurrent (50/51), and loss of excitation. Optional arc-flash sensing adds an extra layer of personnel safety. Learn more about Generator Excitation Control and how it ties into these protections.

Here’s the good news: generator control and monitoring can be added to virtually any generator, from brand-new units to decades-old workhorses. The approach varies depending on what you’re working with, but there’s almost always a solution.

Modern generators with electronic controls are the easiest to upgrade. These units already have sophisticated sensor networks and digital communication built in. Adding remote monitoring usually means connecting to the existing data systems and installing communication hardware. It’s like adding a smartphone to a system that already speaks digital.

Older generators without electronic controls require a bit more creativity, but they’re definitely not lost causes. These systems need additional sensors and interface hardware to bridge the gap between mechanical systems and digital monitoring. Think of it as teaching an old dog new tricks – it takes some patience, but the results are worth it.

ECM-controlled engines (Electronic Control Module) offer the most comprehensive monitoring options. These engines already monitor dozens of parameters and communicate digitally. Adding remote monitoring typically involves tapping into the J1939 data bus and adding communication hardware.

Historic generator sets from the pre-digital era need more basic monitoring approaches. These systems focus on fundamental parameters like oil pressure, coolant temperature, and electrical output. While they won’t have all the bells and whistles of modern systems, they’ll still provide essential remote monitoring capabilities.

Aftermarket systems are specifically designed to work with existing generators regardless of age or manufacturer. These universal solutions can monitor essential functions by connecting to existing sensors or adding new ones as needed.

Our Generator Controllers in Miami are designed to work with a wide range of generator types and can be customized for specific retrofitting requirements.

Choosing the right communication method is like picking the right tool for the job – it depends on your specific situation. Let’s break down your options:

| Communication Method | Reliability | Cost | Coverage | Bandwidth | Security | Best For |

|---|---|---|---|---|---|---|

| Cellular (LTE) | High | Medium | Excellent | Good | Good | Most applications |

| Ethernet | Very High | Low | Limited | Excellent | Excellent | Facilities with network infrastructure |

| Wi-Fi | Medium | Low | Limited | Good | Medium | Short-range applications |

| Satellite | High | High | Global | Limited | Good | Remote locations |

Cellular communication has become the go-to choice for most facilities. LTE networks provide reliable coverage almost everywhere, reasonable ongoing costs, and solid performance for monitoring applications. It’s like having a dedicated phone line for your generator – simple, reliable, and always connected.

Ethernet connections offer rock-solid reliability and excellent security, but they require existing network infrastructure at the generator location. If your generator is close to your main facility and you have network access available, this is often the best choice.

Wi-Fi connectivity works great for generators within range of existing wireless networks. Setup is usually straightforward, and ongoing costs are minimal. However, reliability can be affected by distance, interference, and network congestion – think of it as the convenience option that works well when conditions are right.

Satellite communication serves remote locations where cellular towers fear to tread. While more expensive than other options, satellite provides global coverage and reliable connectivity for critical applications in remote areas.

Location plays a huge role in your decision. Urban areas typically have excellent cellular coverage, while rural or remote locations may need satellite communication. Bandwidth requirements for generator monitoring are typically modest, so most communication methods handle the data load easily.

Security considerations vary by method. Ethernet and VPN connections typically offer the highest security, while cellular and Wi-Fi require additional security measures to protect your data.

Security concerns are completely understandable – you’re essentially putting your backup power system online, and that deserves serious protection. Modern generator control and monitoring systems take security seriously with multiple layers of protection.

Data encryption protects your information during transmission between the generator site and monitoring platforms. Industry-standard encryption protocols ensure that even if someone intercepts your data, they can’t read it. Think of it as sending your information in a locked box that only you have the key to.

Secure user authentication prevents unauthorized access to your monitoring systems. Multi-factor authentication, strong password requirements, and user access controls ensure that only authorized personnel can access system functions. You can set different access levels – maybe your technicians see diagnostic information while managers access reports and configuration settings.

Cloud security best practices are implemented by reputable monitoring service providers. These include secure data centers, regular security audits, and compliance with industry security standards. Professional monitoring services often have better security than most individual facilities could implement on their own.

Password protection and user access controls allow you to control who can access different system functions. You might give your maintenance team access to diagnostic information while restricting configuration changes to facility managers.

VPN access can be implemented for additional security when accessing monitoring systems over public networks. This creates an encrypted tunnel that protects all communication between users and the monitoring system.

The security landscape continues to evolve, and reputable system providers invest heavily in security measures. They regularly update their systems to address emerging threats and maintain compliance with evolving security standards.

The security of remote monitoring systems is typically much better than the alternative – having no monitoring at all and finding problems only when they cause failures during critical moments.

Generator control and monitoring isn’t just about watching your equipment from afar – it’s about taking complete command of your power infrastructure. When you implement these systems, you’re not just buying technology; you’re investing in a fundamentally better way to manage your backup power.

The change happens quickly. Within weeks of installation, you’ll find yourself checking generator status from your phone instead of walking to the equipment room. You’ll receive maintenance alerts before problems develop instead of finding issues during outages. You’ll have confidence that your backup power is ready when you need it most.

Centralized control changes everything about power management. Instead of treating each generator as a separate piece of equipment, you manage your entire power system as an integrated whole. This holistic approach reveals opportunities for optimization that simply aren’t visible when managing individual components.

The synergy between monitoring systems and existing infrastructure creates benefits that multiply over time. When your generators, transfer switches, and load management systems communicate with each other, they work together more effectively. The result is a power system that’s more reliable, efficient, and cost-effective than the sum of its parts.

System integration becomes crucial as facilities grow more complex. Modern buildings often juggle multiple generators, renewable energy sources, energy storage systems, and sophisticated load management requirements. Without centralized monitoring, managing these interconnected systems becomes overwhelming. With proper monitoring, it becomes straightforward.

Future-proofing your investment means choosing systems that can grow with your needs. The monitoring platform you install today should accommodate additional generators, integrate with emerging technologies, and adapt to changing operational requirements. Modern platforms are designed with this flexibility in mind.

Your power management strategy should consider both current needs and future possibilities. The ability to add generators, integrate renewable energy, or implement advanced load management becomes much easier when you have comprehensive monitoring and control systems providing the foundation.

At MTS Power Products, we understand the unique challenges of power system management in South Florida’s demanding environment. Our McPherson Controls line incorporates advanced monitoring capabilities with programmable displays and improved switch mechanisms for superior control and safety. These aren’t just features – they’re solutions to real problems that facility managers face every day.

Being located just minutes from Miami International Airport and the Port of Miami gives us a unique advantage in serving customers worldwide. We can deliver custom generators, transfer switches, and comprehensive power management solutions anywhere they’re needed. Our direct manufacturing capabilities mean you get exactly the right solution for your specific requirements, not a one-size-fits-all approach.

The investment in centralized generator control and monitoring pays dividends in multiple ways. You’ll see improved reliability, reduced costs, and better operational efficiency. But perhaps most importantly, you’ll gain the peace of mind that comes from knowing your backup power systems are ready when you need them most.

For expert advice and top-tier components like generator voltage regulators, explore our solutions. Our team of experts can help you design and implement the perfect monitoring and control solution for your specific needs.

The future of power management is here, and it’s more accessible than ever. Take command of your power system today and find the difference that comprehensive monitoring and control can make for your facility’s reliability, efficiency, and peace of mind.