Buy Direct

from the Manufacturer

Sell our Products

Become a Distributor

Discounts

on volume purchases

Visit Us

at our Miami office

from the Manufacturer

Become a Distributor

on volume purchases

at our Miami office

When standard power solutions fall short, custom generator solutions provide the precision, reliability, and efficiency that critical operations demand. Unlike one-size-fits-all units pulled from a catalog, a custom-engineered generator is a power system carefully designed for your application’s unique requirements—from precise power output and fuel type to specialized enclosures and advanced control systems that standard units simply cannot provide.

For MTS Power Products customers, this goes beyond just picking a bigger or smaller unit. As a direct manufacturer based in Miami, Florida, MTS designs and builds generator sets, automatic transfer switches, and control systems in-house. That means engineering and fabrication teams can coordinate every detail of your system—from the alternator and engine package to McPherson Controls panels and voltage regulators—to deliver a turnkey solution instead of a patched-together assortment of parts.

The difference between an off-the-shelf product and a custom solution lies in the engineering details that address specific operational challenges.

For consulting engineers and facility managers, the choice of a power system is a significant long-term commitment. Industry analysis from organizations like the Electrical Generating Systems Association (EGSA) highlights that this decision can influence a facility’s operational reliability and financial performance for decades. This is why for most critical applications, there are no truly “standard” power solutions.

Organizations from hospitals to data centers increasingly turn to custom-engineered systems to solve complex power challenges. For example, one manufacturer struggled with poor power quality and rising utility costs for years before developing one of Canada’s first industrial microgrids—a 4MW custom solution that transformed their operations. Similar benefits can be seen in well-designed systems from major brands such as Caterpillar and Cummins, which offer extensive technical resources and product documentation that can help specifiers understand best practices when evaluating any custom power solution.

The difference between adequate power and optimal power often comes down to engineering expertise, not just equipment selection. Working directly with a manufacturer like MTS Power Products, with in-house design, fabrication, McPherson Controls, and worldwide delivery from Miami, ensures that your custom generator solutions are custom precisely to your environment, your loads, and your long-term operational strategy.

Modern custom generator solutions must also address environmental concerns and sustainability goals. Custom systems can be engineered to meet or exceed EPA Tier 4 emissions standards, incorporating advanced exhaust after-treatment systems that significantly reduce NOx and particulate matter emissions. For facilities pursuing LEED certification or corporate sustainability initiatives, custom generators can be designed with features like:

These environmental features not only reduce the carbon footprint of backup power systems but can also qualify facilities for utility incentives, tax credits, and improved insurance rates. MTS Power Products works with customers to identify opportunities for sustainable power solutions that align with both operational needs and environmental objectives.

Custom generator solutions further reading:

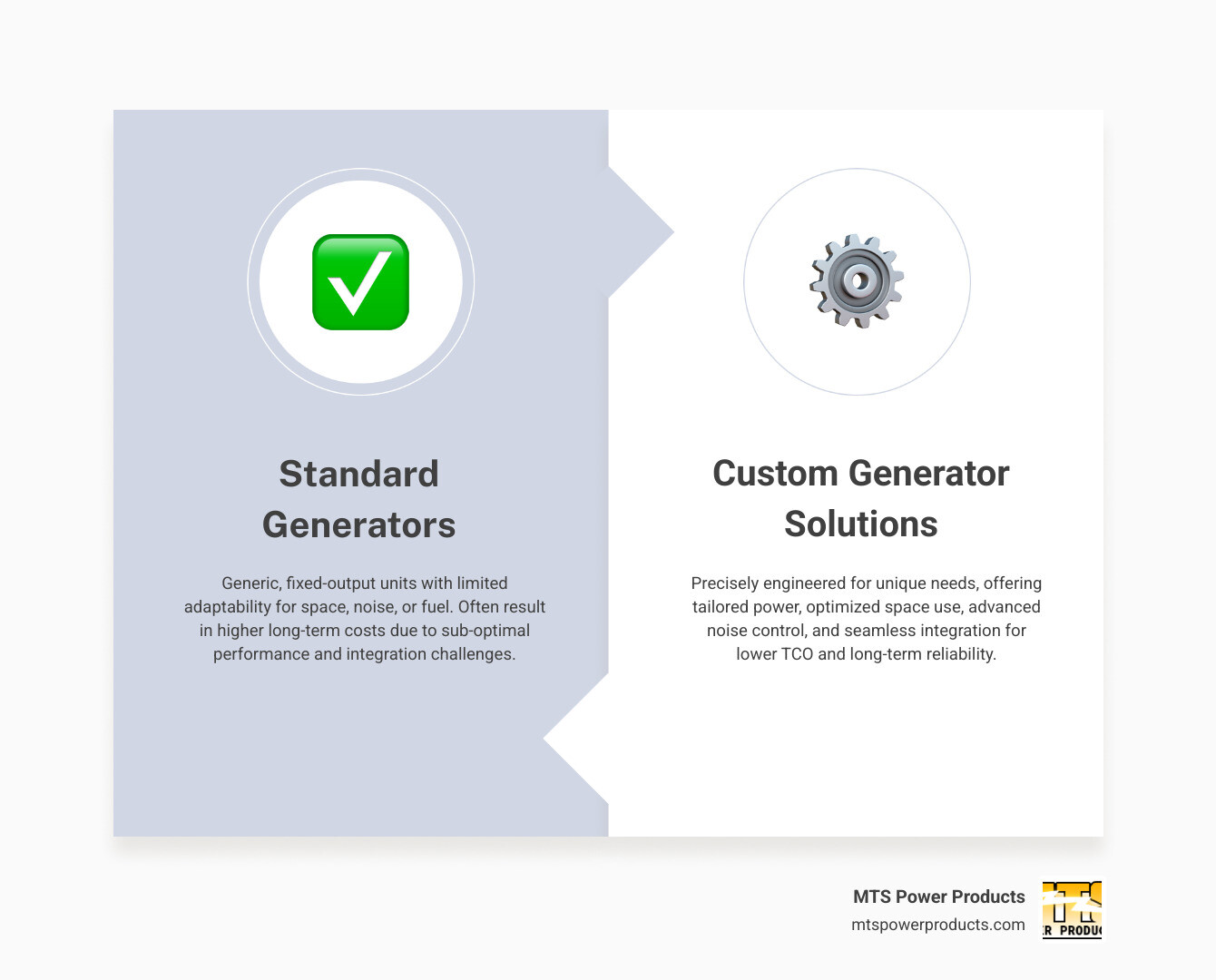

When it comes to securing reliable power, many businesses initially consider standard, off-the-shelf generator units. They seem like a straightforward choice. However, experience across countless critical applications—especially in hurricane-prone regions like South Florida—shows that “ordinary doesn’t fit.” This is precisely where custom generator solutions shine, offering a suite of tangible benefits that far outweigh the one-size-fits-all approach.

Let’s consider a direct comparison:

| Feature | Standard (Off-the-Shelf) Generator | Custom Generator Solution |

|---|---|---|

| Power Output | Fixed power ratings (e.g., 100kW, 250kW, 500kW). Often leads to oversizing or undersizing. | Precisely engineered to match your exact load profile (7kW to 3000kW+), preventing inefficiency and premature wear. |

| Footprint & Space | Standard, fixed dimensions. May require costly site modifications to fit. | Designed to fit your exact space constraints, including rooftops, basements, or irregular-shaped rooms. |

| Noise Level | Basic enclosure with limited sound attenuation. Often exceeds noise ordinances in sensitive areas. | Engineered with custom sound-attenuated enclosures to meet strict noise regulations (e.g., hospital or residential zones). |

| Fuel Type | Typically limited to a single fuel type, usually diesel. | Flexible fuel options including diesel, natural gas, propane, or redundant bi-fuel systems to meet site and cost needs. |

| System Integration | Basic control panel with limited ability to integrate with other building systems. | Advanced, programmable controls (like McPherson Controls) for seamless integration with ATS, switchgear, BMS, and microgrids. |

| Total Cost of Ownership | Lower initial purchase price, but higher long-term costs due to fuel inefficiency, potential site modification, and higher maintenance. | Higher initial investment, but a lower total cost of ownership (TCO) through optimized fuel consumption, reduced maintenance, and longer lifespan. |

Whether you are protecting a single commercial building or a multi-site portfolio, partnering with a specialist like MTS Power Products in Miami ensures that your system is engineered, built, and supported by a team that understands both local conditions and global standards—and can deliver custom solutions worldwide.