Buy Direct

from the Manufacturer

Sell our Products

Become a Distributor

Discounts

on volume purchases

Visit Us

at our Miami office

from the Manufacturer

Become a Distributor

on volume purchases

at our Miami office

Commercial backup generator maintenance is the difference between power when you need it most and costly downtime when disaster strikes. Regular upkeep keeps your generator ready to handle emergencies, prevents expensive repairs, and extends equipment life by years.

Essential maintenance tasks include:

When power outages hit manufacturing facilities or severe weather threatens communities, a well-maintained generator starts reliably and runs smoothly. Poor maintenance, however, leads to generator failure at the worst possible moment – leaving businesses without power and families in the dark.

The cost of prevention is always less than the price of emergency repairs. A generator that receives proper care can run for decades, while neglected units often fail within just a few years of installation.

Regular maintenance also keeps your warranty valid and ensures your generator meets safety standards. Most importantly, it gives you peace of mind knowing your backup power will work when everything else fails.

Basic commercial backup generator maintenance vocab:

Your commercial backup generator is like a reliable friend who’s always there when you need them most. But just like any good friendship, it needs attention and care to stay strong. Commercial backup generator maintenance isn’t just about keeping equipment running – it’s about protecting your entire operation from the unexpected.

Here’s a sobering fact: 70% of generator failures happen because of poor maintenance. That’s not a small oversight – that’s a massive problem that could leave your business in the dark when you need power most. The good news? These failures are completely preventable with the right care.

Proactive care saves you serious money in the long run. Think about it this way: the average power outage costs a small business $3,000 per hour. For larger operations, that number can climb much higher. When you invest in regular maintenance, you’re not spending money – you’re protecting it.

Regular upkeep helps you avoid those expensive emergency repair calls that always seem to happen at the worst possible time. It also extends your generator’s life significantly. A well-maintained unit can serve you faithfully for 20 years or more, while a neglected one might give up after just a few years.

But the real value goes beyond dollars and cents. There’s something priceless about knowing your generator will start when the lights go out. That peace of mind lets you focus on running your business instead of worrying about “what if” scenarios.

The National Fire Protection Association takes generator maintenance seriously too, emphasizing that regular care isn’t just about reliability – it’s about safety. A properly maintained generator protects both your people and your property.

At MTS Power Products, we build our generators and McPherson Controls with advanced features and high safety standards because we understand how important that peace of mind really is. When the storm hits or the grid fails, you’ll be glad you took the time to care for your generator properly.

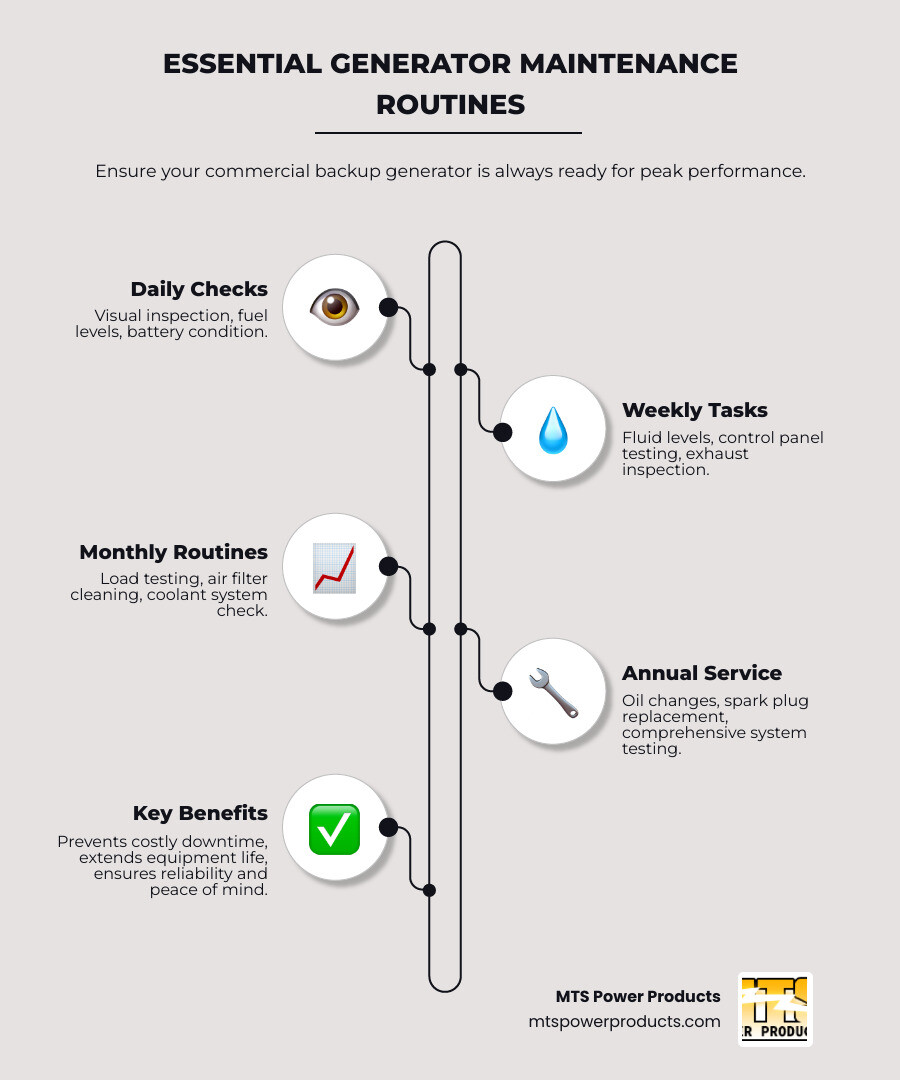

Just like a car needs its regular oil changes and tire rotations, your commercial backup generator thrives on a consistent schedule of care. These routine checks are your first line of defense against unexpected issues.

Even on your busiest days, a quick visual inspection can go a long way.

Once a week, dedicate a bit more time to these crucial checks.

Monthly tasks are a bit more involved but vital for ensuring your generator is truly ready to perform under pressure.

These routine tasks, while seemingly small, contribute immensely to the overall health and reliability of your commercial backup generator.

Think of your generator like a trusted friend who’s always there when you need them most. Just like any good friendship, it needs deeper attention from time to time. While your daily and weekly checks keep things running smoothly, semi-annual and annual commercial backup generator maintenance routines are where the real magic happens.

These comprehensive services dig into your generator’s heart and soul, ensuring it’s ready to perform when everything else fails. This is typically when you’ll want to call in the professionals – people who understand generators inside and out, much like our team at MTS Power Products.

Every six months, your generator deserves some extra love. Electrical connections need inspection and tightening – loose connections are like weak handshakes, they don’t inspire confidence and can lead to serious problems or even fire hazards.

Your generator’s belts and hoses work hard behind the scenes. Check those belts for proper tension (they shouldn’t be too tight or too loose) and look for signs of wear. Inspect hoses for cracks or leaks – these humble components keep everything flowing smoothly.

Fuel quality becomes especially important during these deeper inspections. Diesel generators can develop what’s charmingly called “diesel bug” – microbial growth that can clog your system. Nobody wants bugs in their backup power! Replace fuel filters as recommended and check that your fuel is still in good condition.

Once a year, or after 100-200 operating hours (whichever comes first), your generator needs the full spa treatment. This isn’t just maintenance – it’s an investment in peace of mind.

Oil changes are non-negotiable. Your generator’s oil gets dirty and contaminated over time, just like your car’s. Fresh oil with a new filter keeps everything running smoothly and prevents costly engine damage.

Here’s where things get exciting – load bank testing. This is like putting your generator through boot camp. A load bank connects to your generator and forces it to work at full capacity for several hours. It’s the ultimate stress test that burns off carbon deposits, cleans the engine, and proves your generator can handle whatever you throw at it during a real emergency.

The cooling system gets a complete overhaul during annual service. This includes flushing old coolant, adding fresh coolant, and ensuring the radiator is spotless. A properly cooled generator is a happy generator – overheating can turn your reliable backup into an expensive paperweight.

Your fuel system receives thorough attention beyond just changing filters. Technicians check fuel lines, pumps, and inspect fuel injectors to ensure they’re spraying fuel correctly. For diesel generators, this inspection is especially crucial since fuel can degrade over time.

Battery replacement typically happens every 2-3 years. Even though you check your battery regularly, being proactive prevents that sinking feeling when your generator won’t start during an outage.

The air filter gets completely replaced during annual service, even if you’ve been cleaning it regularly. Think of it as giving your generator fresh lungs to breathe with.

Some generators need valve lash adjustment annually or every other year. This fine-tuning maintains engine efficiency and keeps everything purring like a well-fed cat.

Finally, the comprehensive electrical system check includes your Automatic Transfer Switch (ATS). This unsung hero seamlessly switches your power sources when the grid goes down. At MTS Power Products, we know ATS systems inside and out – ensuring yours works perfectly is just as important as maintaining the generator itself.

By following these semi-annual and annual routines, you’re not just maintaining equipment – you’re investing in your business’s continuous operation and your own peace of mind. A well-maintained generator doesn’t just start when you need it; it runs reliably for years to come.

Keeping track of all these maintenance tasks can feel overwhelming, but having a systematic approach makes it manageable. Think of this checklist as your generator’s health record – a simple way to ensure nothing falls through the cracks during your commercial backup generator maintenance routine.

Your engine and fuel system form the heart of your generator’s operation. Start with checking your fuel levels regularly, ensuring you have enough supply for extended outages. For diesel generators, pay special attention to fuel quality – look for water, sediment, or signs of that pesky microbial growth that can wreak havoc on your system. Don’t forget about your fuel filters, which typically need replacement annually or more often with heavy use.

The oil level and quality deserve daily or weekly attention, with complete changes annually or according to your hour meter. Your oil filter should be replaced with every oil change – they’re a team that works best when fresh together. The air filter needs monthly inspection and annual replacement to keep your engine breathing easy.

If you’re running a gas or propane unit, spark plugs need annual inspection and replacement. All generators benefit from regular checks of belts and hoses for wear, cracks, and proper tension – typically every six months. Your coolant system requires weekly level checks and annual flushing, while the radiator and cooling fins should stay clean and debris-free. Finally, make visual inspections for any engine leaks part of your daily routine.

Your electrical system and controls keep everything running smoothly. Battery condition is crucial – check terminals for corrosion and electrolyte levels if applicable, replacing batteries every 2-3 years. Keep those battery connections clean and tight. Annual inspection of wiring and connections helps catch fraying, damage, or loose connections before they cause problems.

Test your control panel functionality regularly, including alarms and indicators. Our McPherson Controls line makes this easier with intuitive programmable displays for improved monitoring. Don’t overlook your Automatic Transfer Switch (ATS) – it needs annual inspection and testing to ensure seamless power transfer when you need it most.

The exhaust system might seem simple, but it’s vital for safe operation. Check exhaust pipes for leaks, cracks, and obstructions, and inspect the muffler for damage or rust.

Your generator’s physical and environmental conditions matter more than you might think. Keep the generator enclosure clean and free of debris, pests, and obstructions. Ensure ventilation openings stay clear for proper airflow. Check for any signs of fluid spills and address them immediately. Implement rodent and pest control measures – you’d be surprised how much damage a determined squirrel can cause!

Testing and performance verification ties everything together. Make sure your exercise cycle is set and occurring regularly through automatic scheduling. Perform load testing monthly with light loads and annually with full load bank testing to ensure peak performance and prevent wet stacking. Regular alarm system tests verify that all safety shutdowns and alarms work when needed.

While your facility staff can handle many of these routine checks, comprehensive annual services and complex repairs are best left to certified professionals. As a direct source for professional quality generator sets and parts, MTS Power Products provides the components and expertise needed to keep your generator running reliably for years to come.

We get plenty of questions from business owners who want to keep their generators running smoothly. Here are the answers to the most common concerns about commercial backup generator maintenance.

The golden rule for most standby generators is simple: annual service or every 100-200 hours of operation, whichever comes first. Think of it like your car’s annual inspection – it’s that yearly check-up that catches problems before they become disasters.

For most commercial backup generators that mainly run during power outages and weekly exercise cycles, once a year is perfect. This comprehensive service should cover everything from oil changes to load bank testing.

But here’s where it gets interesting – if you’re using your generator as a workhorse for prime power or running it frequently for long periods, you’ll need more frequent attention. Maybe every 250-500 hours instead. And if your generator lives in a dusty warehouse or faces extreme weather conditions, it might need extra TLC too.

The best advice? Check your owner’s manual first. Every generator has its own personality, and manufacturers know their equipment best.

Diesel generators are tough cookies, but they have three areas that need special attention: lubrication, cooling system, and fuel system care.

Lubrication is absolutely critical because diesel engines work hard under high pressure and heat. Clean oil and fresh oil filters aren’t just nice-to-haves – they’re essential for preventing expensive engine damage. Think of oil as your engine’s lifeblood.

The cooling system works overtime in diesel generators. These engines run hot, so your radiator, hoses, and coolant need to be in perfect shape. A overheated diesel engine can turn into a very expensive paperweight quickly. Keep those radiator fins clean and check coolant levels religiously.

But the fuel system is where diesel generators really show their unique needs. Diesel fuel can go bad sitting in your tank, especially in standby units. You might deal with water contamination or even microbial growth (lovingly called “diesel bug” in the industry). Regular fuel filter changes, draining the fuel-water separator, and periodic fuel quality testing keep your generator happy. Load bank testing is extra important for diesel units to prevent wet stacking – basically burning off unburned fuel that can gum up your exhaust system.

Maintaining a backup generator is like caring for a reliable friend who’s always there when you need them. It’s all about consistent attention and knowing when to call in the professionals.

Start with the basics you can handle yourself. Regular visual inspections catch obvious problems early – look for leaks, debris, or anything that seems off. Keep an eye on your oil level, coolant, and fuel. These fluids are like vital signs for your generator.

Your battery deserves special attention because it’s the most common reason generators won’t start when you need them. Keep terminals clean and connections tight. The air filter needs regular cleaning too – a dirty filter chokes your engine and hurts performance.

For diesel generators especially, fuel quality matters more than you might think. Change those fuel filters regularly and test your fuel periodically to avoid nasty surprises.

Load testing is your generator’s workout routine. Just like people need exercise to stay fit, generators need to run under load to stay healthy and prevent problems like wet stacking.

Don’t forget about the components that work behind the scenes – belts, hoses, spark plugs for gas units, and your exhaust system all need periodic attention.

The smart approach combines what you can do yourself with professional expertise. While your team can handle daily and weekly checks, comprehensive annual servicing requires certified technicians who understand the intricate details. At MTS Power Products, we provide not just high-quality generator sets and parts, but also the knowledge to keep them running at peak performance. After all, your generator’s job is to be ready when everything else fails.

Your commercial backup generator is like having a reliable friend who’s always there when you need them most. Just like any good friendship, it requires care, attention, and regular check-ins to keep things running smoothly.

Throughout this guide, we’ve walked through the essential steps of commercial backup generator maintenance – from those quick daily glances to the comprehensive annual tune-ups. Each task, whether it’s checking oil levels or running load bank tests, plays a vital role in keeping your generator ready for action.

The math is simple: scheduled maintenance costs far less than emergency repairs or business downtime. A generator that receives proper care can serve your business faithfully for twenty years or more. That’s decades of reliable backup power, protecting your operations from unexpected outages.

Generator longevity isn’t just about following a maintenance schedule – it’s about having the right equipment and support from the start. At MTS Power Products, we understand that every business has unique power needs. Our McPherson Controls line brings advanced features like remote monitoring and programmable displays right to your fingertips, making maintenance tasks easier and more effective.

Being centrally located in Miami, Florida, just minutes from Miami International Airport and the Port of Miami, we’re perfectly positioned to serve customers worldwide. Whether you need a custom generator, transfer switch, or replacement parts, we’re your direct source for professional-quality power solutions.

When the next storm hits or the grid goes down unexpectedly, you’ll have peace of mind knowing your generator is ready. That’s the real value of proper maintenance – not just keeping a machine running, but protecting everything that matters to your business.

Let’s work together to keep your backup power system in peak condition. After all, when the lights go out everywhere else, yours should stay on.