Buy Direct

from the Manufacturer

Sell our Products

Become a Distributor

Discounts

on volume purchases

Visit Us

at our Miami office

from the Manufacturer

Become a Distributor

on volume purchases

at our Miami office

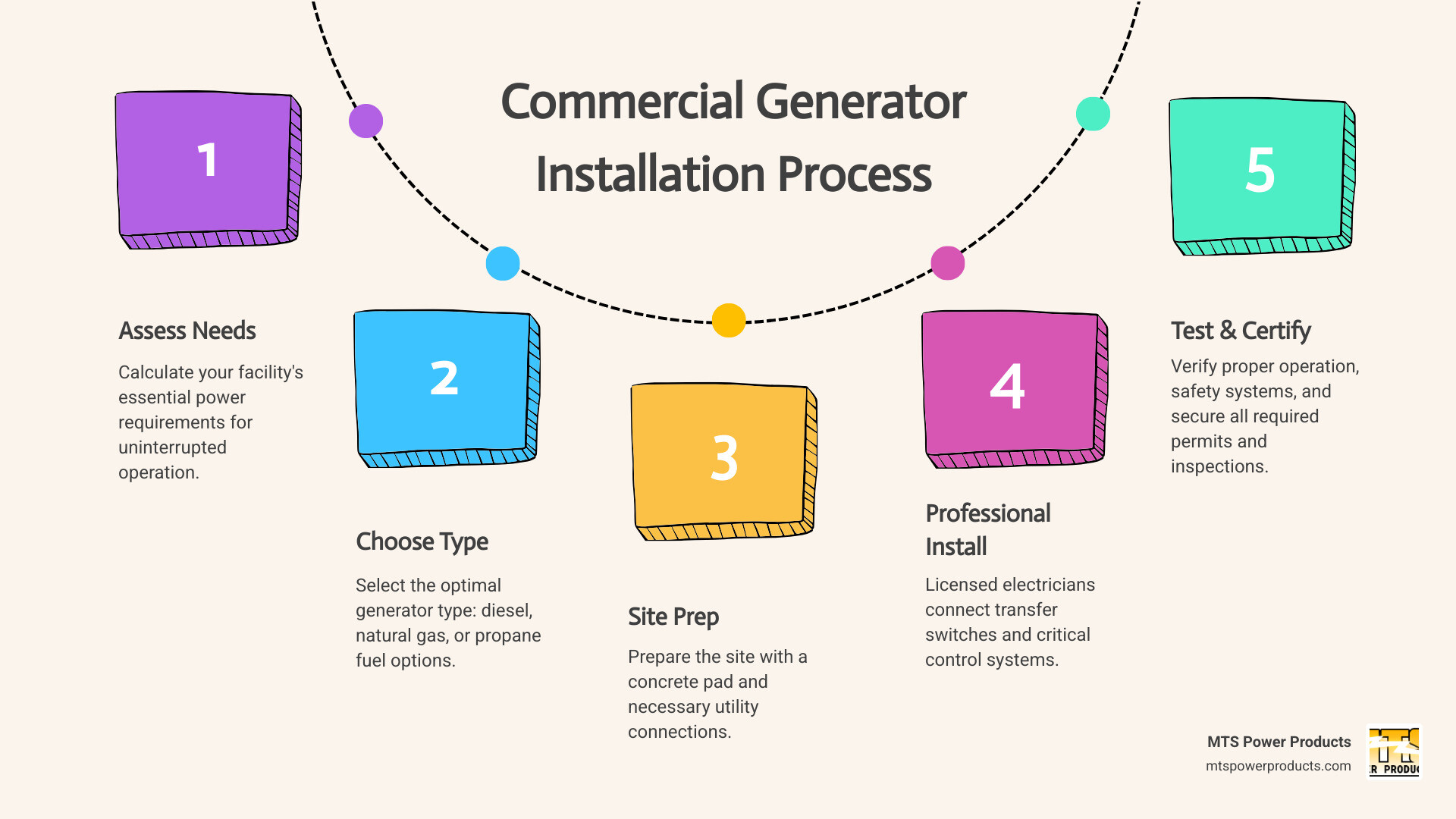

Commercial backup generator installation involves several key steps that ensure your business stays powered during outages:

When power goes out, businesses lose money fast. Manufacturing plants shut down production lines. Office buildings can’t operate computers or lighting. Critical systems like security and HVAC stop working completely.

The stakes are high. A single power outage can cost businesses thousands of dollars per hour in lost productivity, spoiled inventory, and missed deadlines. For facilities managers like those at manufacturing plants, keeping operations running isn’t just important – it’s essential for safety and profitability.

Installing a commercial backup generator protects your business from these costly disruptions. But the installation process requires careful planning, proper sizing, and professional expertise to ensure reliable operation when you need it most.

The right generator installation gives you peace of mind. Your critical systems stay online. Your employees stay safe. Your business keeps running no matter what happens to the power grid.

Commercial backup generator installation vocabulary:

Getting your commercial backup generator installation right starts with one crucial question: what exactly needs to stay powered when the lights go out? It’s like being asked to pack only the essentials for an emergency trip – you need to know what truly matters versus what would just be nice to have.

Every facility is different, and that’s why we can’t just guess at your power needs. A manufacturing plant might need to keep critical production equipment running to prevent costly shutdowns or safety hazards. An office building might prioritize servers, security systems, and emergency lighting to keep operations going and people safe.

Energy requirements form the foundation of your generator sizing. We start by walking through your facility and identifying every system that absolutely must stay online during an outage. This includes everything from your main production equipment to smaller but critical systems like emergency lighting, fire safety equipment, and communication systems.

But here’s where it gets tricky – we also need to consider peak demand. This isn’t your average power usage on a quiet Tuesday afternoon. Peak demand is what happens when multiple systems kick on at the same time, like when your HVAC system starts up while your production line is running at full capacity.

Motor starting loads can be particularly sneaky. That equipment might run smoothly at 10 kilowatts, but it could need 30 kilowatts just to get started. Miss this detail, and you’ll have a generator that works great until it doesn’t – right when you need it most.

The good news? A thorough power audit takes all the guesswork out of the equation. We’ll calculate the combined wattage and amperage of your essential systems, factor in those tricky starting loads, and make sure your generator can handle whatever your facility throws at it. Getting this foundation right means your backup power system will actually back you up when it counts.

Now that we know exactly what your facility needs, it’s time for the fun part – picking your perfect generator! Think of this like choosing a reliable partner for your business. You want something that’ll be there when you need it most, won’t let you down, and fits your budget.

The biggest decision you’ll face during commercial backup generator installation is fuel type. It’s like choosing between different cars – each has its own personality and benefits.

Diesel generators are the tough guys of the generator world. They’re built to last and pack serious power into a compact package. Diesel fuel stores well for months (even years with proper treatment), so you don’t have to worry about it going bad. These generators love heavy-duty work and are perfect for manufacturing plants or facilities that need serious power. The trade-off? You’ll need space for fuel storage tanks and proper permits for handling diesel fuel.

Natural gas generators are the convenient choice. They connect directly to your building’s gas line, so you never run out of fuel or need to schedule deliveries. They run cleaner than diesel and typically cost less to operate day-to-day. It’s like having city water versus a well – always there when you turn it on. Just keep in mind that if a major disaster takes out gas lines, you might lose your fuel supply too.

Propane generators offer a nice middle ground. Propane burns cleaner than diesel but doesn’t rely on utility lines like natural gas. You can store it on-site in tanks, and it won’t go bad over time. The downside is that tanks have limited capacity, so extended outages might mean arranging for refills.

Getting the sizing right is absolutely critical. Too small, and your generator will struggle like a compact car trying to tow a boat. Too big, and you’re wasting money on fuel and equipment you don’t need. Oversized generators also tend to have shorter lifespans because they don’t run efficiently at low loads.

Our team takes the guesswork out of sizing. We calculate not just your normal power needs, but also those surge loads when multiple motors start up at once. It’s detailed work, but getting it right means your generator will handle whatever you throw at it. For a deeper dive into the calculations, check out our guide on how to size a commercial backup generator.

With the right generator selected, we move into the exciting part: bringing your commercial backup generator installation to life. This is where careful planning transforms into real-world protection for your business. Think of it like building a fortress around your operations – every detail matters.

Before your shiny new generator arrives, we need to roll up our sleeves and get the foundation right. Your generator is going to be heavy – we’re talking several tons of equipment that needs a rock-solid home.

The concrete pad is where everything starts. This isn’t just any old slab of concrete; it’s a carefully engineered foundation that keeps your generator level and stable for years to come. We make sure there’s plenty of room around the unit for future maintenance access – because nobody wants to find they can’t reach the oil filter when it’s time for service.

Ventilation planning is crucial too. Your generator needs to breathe, and that means planning for proper airflow to keep things cool and safely direct exhaust fumes away from buildings and people. We also think about your neighbors and employees by considering noise mitigation strategies that keep everyone happy and compliant with local regulations.

For natural gas units, this stage includes running the gas lines safely and according to code. For diesel generators, we prepare the area for fuel tank placement and all the associated piping. Every connection needs to be perfect from day one.

Here’s where we need to have a serious conversation: this is absolutely not a weekend DIY project. Commercial backup generator installation involves complex electrical work, fuel connections, and integration with your facility’s power systems. One mistake can be dangerous – and expensive.

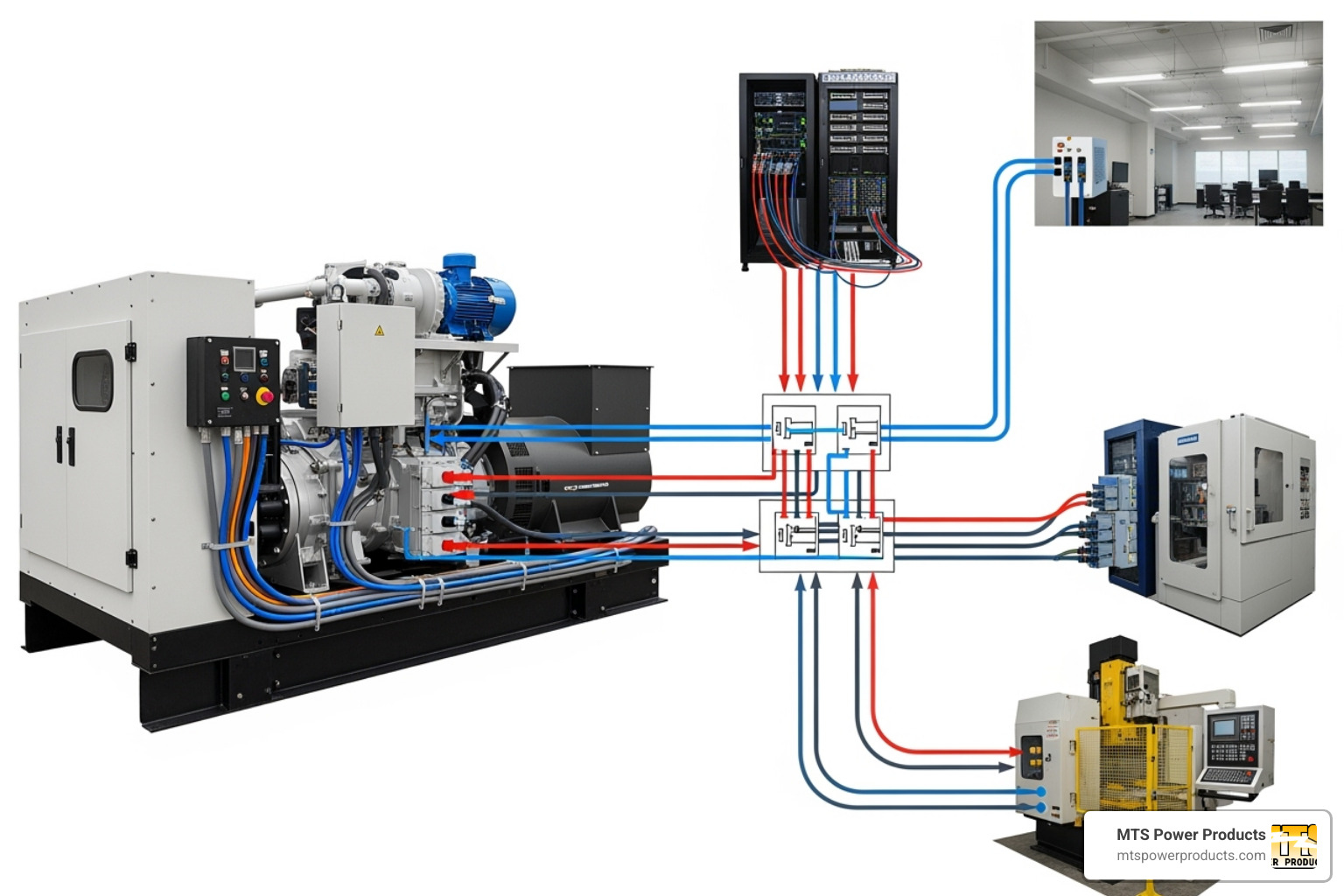

Our licensed electricians and certified technicians handle every aspect of the installation. The real star of this show is the Automatic Transfer Switch (ATS) – this smart device is like having a vigilant guard watching your power 24/7. When the utility power goes out, the ATS springs into action, disconnecting your facility from the grid and seamlessly switching to generator power, often in just seconds.

When utility power comes back, the ATS handles the transition back to grid power and signals your generator to cool down properly before shutting off. It’s like having an expert electrician on duty around the clock.

At MTS Power Products, we offer a complete range of ATS units, including our own McPherson Controls line with advanced programmable displays. These aren’t just switches – they’re intelligent control systems that give you complete visibility and control over your backup power system.

Our installation team connects everything according to strict electrical codes. The generator talks to the ATS, the control panel integrates with your facility’s systems, and all the wiring and fuel lines are routed safely and professionally.

Safety isn’t just a checkbox for us – it’s the foundation of everything we do. We follow the National Electrical Code (NEC), local building codes, and fire safety regulations to the letter. These aren’t suggestions; they’re requirements that protect your business, your people, and your community.

Permits and inspections are part of the process, not an afterthought. We handle the paperwork and coordinate with local authorities to ensure everything meets or exceeds requirements. Our professional installers know these codes inside and out, so you can rest easy knowing your commercial backup generator installation is done right the first time.

Every connection is tested, every safety system is verified, and every component is commissioned properly. When we hand you the keys to your new backup power system, you can be confident it will perform when you need it most.

Getting the technical installation right is just the beginning. The real success of your commercial backup generator installation comes down to making smart decisions about several critical factors that will impact your system for years to come.

Think of choosing your generator’s location like picking the perfect spot for your house – it needs to work today and twenty years from now. Accessibility is your first priority. Your maintenance team needs to get to the unit easily for routine checks, and if you’re using diesel or propane, fuel delivery trucks need a clear path. Nothing’s worse than finding your generator is unreachable when it needs service most.

Noise impact deserves serious consideration, especially in mixed-use areas. Commercial generators aren’t exactly quiet neighbors. We need to think about how the sound will affect nearby offices, residential areas, or even your own workspace. Sometimes specialized enclosures or strategic placement can solve noise issues before they become problems.

Proper ventilation keeps your generator breathing easy. These units generate significant heat and need adequate airflow for cooling and safe exhaust of fumes. The location must allow air to flow freely around the unit – cramped spaces lead to overheating and potential safety hazards.

For fuel considerations, natural gas units work best close to the main gas line to minimize piping costs. Diesel and propane systems need thoughtful placement near their fuel storage areas. Environmental factors like flood zones, weather exposure, and security also play important roles in location selection.

Your fuel choice during the selection phase has real installation implications that affect complexity and cost. Natural gas installations require a dedicated gas line sized properly for your generator’s needs. This often means coordinating with your local gas utility company and potentially upgrading your existing service.

Diesel systems bring their own set of requirements. You’ll need a compliant fuel storage tank with double-wall construction, spill containment systems, and proper fire suppression measures. These regulations can vary significantly depending on your location, so local knowledge matters.

Propane installations require secure outdoor tank placement and strict adherence to fire safety codes. Each fuel type adds its own layer of infrastructure requirements to your commercial backup generator installation project.

Nobody gets excited about permits and regulations, but they’re absolutely essential for a safe, legal installation. Local building and electrical codes govern everything from wiring standards to the structural requirements for your generator pad. Getting this wrong can mean costly do-overs later.

Zoning laws might restrict where you can place your generator, how much noise it can make, or how it looks from the street. This is especially important in urban areas or mixed-use zones where neighbors and local officials pay close attention to new installations.

Environmental regulations from the EPA can apply depending on your generator’s size and fuel type. These cover emissions standards, fuel storage requirements, and spill prevention measures. Fire safety standards from the National Fire Protection Association provide crucial guidelines for safe installation and operation.

Here in South Florida, we’ve steered these regulatory waters countless times. Every commercial backup generator installation we complete meets all applicable codes and standards, giving you confidence that your system is both safe and legally compliant.

We love talking with business owners about commercial backup generator installation – and over the years, we’ve noticed the same thoughtful questions coming up again and again. Let’s explore the ones that matter most to you.

Here’s the honest truth: asking about generator installation costs is a bit like asking “How much does a building cost?” The answer depends on what you’re building and where you’re building it.

Generator size and type make the biggest difference in your investment. A smaller natural gas unit for a small office will cost significantly less than a large diesel generator for a manufacturing facility. Then there’s the fuel infrastructure – natural gas requires gas line work, while diesel means fuel tanks and associated safety systems.

Site complexity can really impact your budget too. Is your location easy to access, or will we need to steer tight spaces and complex routing for electrical and fuel lines? Do local noise ordinances require special sound-dampening enclosures? These factors all play a role.

The automatic transfer switch is another key component. A basic ATS for simple loads costs less than our advanced McPherson Controls units with programmable displays and remote monitoring capabilities – but the added features often justify the investment for critical operations.

Don’t forget about permits and inspections – these vary by location but are essential for legal operation. Professional installation by licensed technicians represents a significant portion of the investment, but it’s money well spent for safety and reliability.

While we can’t give you a number without knowing your specific needs, we can tell you this: the cost of installation almost always pales in comparison to what businesses lose during extended outages.

This is where we get really serious for a moment. Yes, absolutely, without question – commercial generators must be professionally installed. We’ve seen too many dangerous situations from attempted DIY installations to ever recommend otherwise.

Think about what’s involved here: high-voltage electrical work that can be lethal if handled incorrectly. Fuel system connections for natural gas, diesel, or propane that pose serious fire and explosion risks if done wrong. Complex integration with your facility’s existing electrical systems that requires deep knowledge of electrical codes.

Our certified installation team understands the intricate dance between your generator, transfer switch, and building electrical systems. They know how to properly size and route fuel lines, ensure adequate ventilation to prevent carbon monoxide buildup, and meet all the safety codes that keep your people and property protected.

Professional installation isn’t just about safety – though that’s reason enough. It’s also about ensuring your system works when you need it most. Improper installation can lead to system failures during outages, leaving you in the dark when you thought you were protected.

At MTS Power Products, our installation teams are licensed, experienced, and intimately familiar with South Florida’s unique requirements. We’ve been doing this long enough to know that cutting corners on installation is never worth the risk.

Getting the size right is absolutely critical – and it’s more complex than many people realize. Undersizing leaves you powerless when you need backup most, while oversizing wastes money and can actually harm your generator’s performance.

The gold standard is a professional load assessment. Our experts will walk through your facility and identify every critical system that needs to stay online during an outage. We’re talking about your essential lighting, computers, HVAC systems, manufacturing equipment, security systems – everything that keeps your business running.

But here’s the tricky part: we don’t just look at how much power these systems use when they’re running normally. Motor starting loads can be three to seven times higher than running loads. When your HVAC system kicks on, or a large motor starts up, there’s a massive surge of power demand. Your generator needs to handle these surges without missing a beat.

Utility statements can be misleading for this purpose. They show your average consumption over time, but they don’t tell you about peak demand or which specific circuits need backup power. They’re useful for getting a baseline understanding, but they shouldn’t be your only guide.

We also think about your future growth plans. Adding new equipment next year? Planning to expand operations? It often makes sense to size your generator with a little headroom rather than needing an upgrade sooner than expected.

For detailed guidance on this crucial decision, we encourage you to read our comprehensive guide on how to size a commercial backup generator. Getting this right from the start saves you headaches and ensures reliable power when you need it most.

When the lights go out, your business doesn’t have to. Throughout this guide, we’ve walked through every crucial step of commercial backup generator installation – from understanding your power needs to selecting the right equipment and ensuring professional installation. It’s not just about buying a generator; it’s about creating a complete power security system that keeps your business running when everything else stops.

The reality is simple: power outages are unpredictable, but your response to them doesn’t have to be. Whether you’re running a manufacturing plant that can’t afford production downtime or managing an office building where security and safety systems are non-negotiable, having the right backup power solution makes all the difference.

At MTS Power Products, we understand that every business has unique power challenges. That’s why we’re more than just a supplier – we’re your partners in power security. As a direct source for professional quality generator sets, automatic transfer switches, and control panels, we eliminate the middleman and deliver exactly what your facility needs.

Our McPherson Controls line represents our commitment to innovation and reliability. These aren’t just standard control panels; they’re sophisticated systems with programmable displays and advanced switch mechanisms that give you complete control over your backup power system. The remote monitoring capabilities mean you can check your generator’s status from anywhere – whether you’re at home, traveling, or managing multiple locations.

Safety isn’t negotiable when it comes to commercial power systems. Every McPherson Controls unit meets the highest safety standards, giving you confidence that your investment protects both your business and your people. The advanced features aren’t just convenient; they’re designed to prevent problems before they happen.

Being centrally located within minutes of Miami International Airport and the Port of Miami means we can serve customers worldwide while maintaining our deep roots in South Florida. We’ve seen how hurricanes and storms can devastate businesses that aren’t prepared. That’s why we’re passionate about helping companies build resilient power systems that stand up to whatever nature throws at them.

From Start to Power – that’s not just our motto, it’s our promise. When you work with MTS Power Products, you’re getting decades of expertise, cutting-edge technology, and the peace of mind that comes from knowing your backup power system will work when you need it most.

Don’t wait for the next outage to remind you how important reliable power is to your business. Invest in professional commercial backup generator installation today, and sleep better knowing your business is protected tomorrow.