Buy Direct

from the Manufacturer

Sell our Products

Become a Distributor

Discounts

on volume purchases

Visit Us

at our Miami office

from the Manufacturer

Become a Distributor

on volume purchases

at our Miami office

Big generators are the backbone of power reliability for businesses and critical facilities. Ranging from 100kW to over 3,000kW, they provide the capacity to keep entire facilities running during outages or serve as primary power in remote locations.

Key Facts About Big Generators:

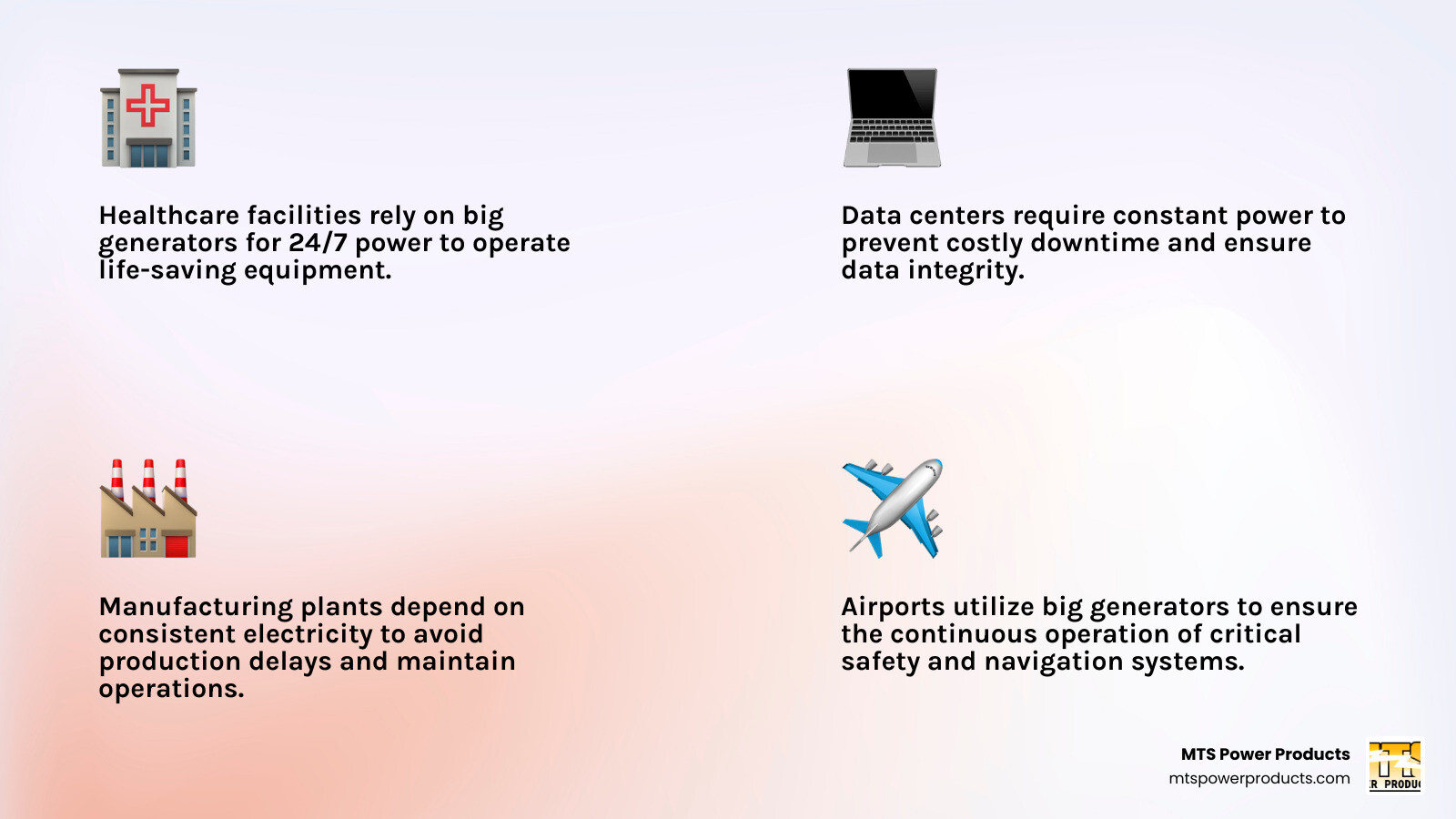

As our economy’s dependence on uninterrupted electricity grows, so does the demand for reliable power. Healthcare facilities, data centers, and manufacturing plants all rely on 24/7 power to prevent data loss, operational delays, and risks to human safety.

Understanding large generators helps facility managers make informed decisions about power backup. These machines offer capacity and reliability that smaller portable units cannot match. The right choice depends on your power needs, fuel availability, and local regulations, with options ranging from robust diesel units to cleaner natural gas systems.

Big generators terms to remember:

When the lights go out, some facilities simply can’t afford to stay dark. Big generators are lifelines that ensure operational continuity, delivering power reliability and business resilience that protect everything from patient care to million-dollar data centers.

More than just keeping the lights on, these generators provide asset protection and ensure safety and security when the grid fails, acting as an insurance policy against the unexpected.

Essential services depend on big generators to function without interruption.

Big generators also power the economy by preventing costly downtime in various sectors.

Having a big generator on-site offers key advantages beyond simply avoiding blackouts.

Selecting the right big generator involves understanding your specific needs. The process starts with sizing calculations and load requirements, followed by considering practical factors like fuel availability and environmental regulations. This guide will walk you through each step.

Your fuel choice shapes everything from operating costs to maintenance. Each option has distinct advantages depending on your situation.

| Feature | Diesel Generators | Natural Gas Generators |

|---|---|---|

| Fuel Source | Diesel fuel, stored on-site | Natural gas pipeline (or propane tanks) |

| Emissions | Higher particulate matter and NOx | Lower emissions, cleaner burning |

| Maintenance | More frequent, due to fuel combustion byproducts | Less frequent, cleaner burning reduces engine wear |

| Availability | Requires fuel delivery and storage | Dependent on natural gas pipeline infrastructure |

| Cost | Generally higher fuel costs, lower upfront unit cost | Lower fuel costs (if piped), potentially higher unit cost |

| Applications | Heavy-duty, remote sites, temporary power, prime power | Standby power, continuous grid-tied applications |

Diesel generators are robust workhorses, ideal for heavy loads, remote sites, or prime power applications. They start quickly and deliver consistent power in harsh conditions.

Natural gas generators are a cleaner, more convenient option if you have pipeline access. With no need for on-site fuel storage, they run quieter and have fewer emissions, making them ideal for urban areas.

Bi-fuel systems offer flexibility by switching between diesel and natural gas, while alternative fuels like propane are available for specific applications.

Big generators are rated differently based on their intended use. Understanding these ratings prevents costly mistakes.

Using a standby-rated generator for a prime power application will lead to premature wear and expensive repairs.

Once you’ve narrowed down the type and rating, it’s time to review the technical details.

For detailed specifications on a gaseous generator model, you can review comprehensive technical documentation.

Understanding environmental and safety standards is crucial for compliance and protecting your investment.

Work with experienced professionals to ensure your generator meets all power requirements and regulatory standards. For more information on a high-capacity diesel model that meets various certifications, you can review its detailed specifications.

Acquiring a big generator is just the first step. Proper installation, mobility options, and regular maintenance are vital for a reliable, long-lasting power solution.

Installing a large generator is a complex project requiring professional expertise.

Many big generators are designed for portability, especially for temporary power needs.

Regular maintenance is essential for reliability and longevity. Neglecting it leads to costly breakdowns.

Here’s a typical generator maintenance checklist:

Here are answers to the most common questions about big generators to help you make an informed decision.

Sizing a generator correctly is critical for reliable backup power. The process involves a detailed load analysis.

First, list all essential equipment, noting both running watts (continuous use) and starting watts (initial surge). The key is accounting for the high starting wattage required by motor-driven equipment like HVAC systems. Your generator must be able to handle this surge.

To calculate the total size, add the single highest starting wattage to the total running wattage of all other equipment. Always add a 20-25% buffer to this total to account for future growth and prevent overloading the generator, which reduces its lifespan. While a home might need 10kW, commercial facilities often require 100kW to 500kW or more.

Runtime depends on the generator’s duty rating and fuel supply.

Fuel is the practical limit. Diesel generators run as long as the tank has fuel, requiring refueling logistics. Natural gas units connected to a pipeline can run continuously without refueling. A properly maintained commercial generator can last 10 to 30 years, operating for thousands of hours.

The Automatic Transfer Switch (ATS) is the brain of your backup power system, ensuring a seamless transition during an outage.

The ATS constantly monitors utility power. When it detects a failure, it signals the generator to start. Once the generator provides stable power (usually within 10-30 seconds), the ATS automatically transfers the building’s electrical load to it. Your facility continues operating without interruption.

When utility power is restored and stable, the ATS transfers the load back and signals the generator to cool down and shut off. This entire process is automatic, providing reliable protection without human intervention, which is crucial for 24/7 facilities.

Choosing the right big generator is like building a safety net for your business. This guide has covered the key selection factors, from understanding your power needs and fuel types to navigating ratings and emissions compliance.

A reliable power strategy, however, involves more than just the generator. Proper installation, quality components like an automatic transfer switch, and professional maintenance with genuine parts are what transform a piece of equipment into true peace of mind.

This is where having the right partner makes all the difference. At MTS Power Products, we understand that reliable power is about keeping your operations running smoothly and protecting your investments.

Our direct manufacturing approach and specialized McPherson Controls line, featuring programmable displays and advanced switch mechanisms, set us apart. Located in Miami near the international airport and port, we deliver custom solutions worldwide with the personal service you expect.

Whether you need a standby unit for emergency backup or a prime power system for continuous operation, we guide you through every step. From sizing calculations to installation and ongoing support, we are your trusted partner in the power products industry.

Find your commercial backup generator solution with us today. Let’s work together to power your future with confidence and reliability.