Why Your Tecumseh Engine Speed Matters

Adjusting Tecumseh governor is a straightforward process that can restore your engine’s performance in just a few minutes. If your snowblower, lawnmower, or generator is running too fast, too slow, or surging under load, a simple governor adjustment often fixes the problem.

Quick Answer: How to Adjust a Tecumseh Governor

- Turn off the engine and disconnect the spark plug wire

- Loosen the governor lever clamp screw (don’t remove it completely)

- Move the throttle lever to wide-open position at the carburetor

- Rotate the governor shaft as far as it will go in the same direction the lever moved

- Hold both in position and tighten the clamp screw

- Reconnect the spark plug and test the engine

Your Tecumseh engine has a governor for the same reason your car has cruise control—to maintain steady speed regardless of the load. When you’re mowing through thick grass or your snowblower hits heavy, wet snow, the governor automatically opens the throttle to keep the engine running at the right speed. Without it, your engine would bog down under load or race dangerously when the load disappears.

Unfortunately, governors can get knocked out of adjustment during maintenance or simply wear over time. The good news? You don’t need to be a small engine expert to fix it. Most governor adjustments take less than 10 minutes with basic hand tools.

Whether you’re John managing backup generators at a manufacturing plant or Rebecca preparing your home generator for hurricane season, understanding this simple adjustment can save you costly downtime and service calls.

Understanding the Tecumseh Governor System

The governor in your Tecumseh engine is a crucial system that maintains consistent engine speed (RPM). It acts like a cruise control, automatically adjusting the throttle to handle changes in load. When the engine is under heavy load, like mowing thick grass, the governor senses the RPM drop and opens the throttle to provide more power. When the load is removed, it closes the throttle to prevent the engine from over-revving and causing damage. This automatic adjustment is vital for engine protection and efficiency. For generators, a stable 3600 RPM is critical to produce consistent electricity, making a functional governor non-negotiable.

Signs Your Governor Needs Adjustment

The symptoms of a misadjusted governor are usually obvious, as they directly impact engine speed control.

- Engine Surging or Hunting: The engine RPM repeatedly speeds up and slows down, as if searching for the right speed. If holding the linkage between the governor arm and carburetor stabilizes the engine, the governor is likely the issue.

- Lack of Power Under Load: The engine runs fine with no load but bogs down or struggles when you engage the mower, snowblower, or generator. This indicates the governor isn’t opening the throttle enough to meet the power demand. A user on a forum described this exact scenario with their Troy-Bilt snowblower after a carburetor rebuild: “It runs great just sitting there. However, under load it doesn’t want to throw snow very well.”

- Over-Revving: A dangerous symptom where the engine races to full throttle uncontrollably, even with no load. This means the governor is failing to close the throttle and can lead to severe engine damage.

- Stalling Under Load: More severe than just a lack of power, the engine stalls completely when a load is applied. This suggests the governor isn’t responding at all.

- Inconsistent Speed: The engine’s RPM fluctuates randomly without any significant change in load, indicating unstable governor control.

If you’re experiencing any of these issues, it’s a good bet that your adjusting Tecumseh governor skills are about to come in handy!

How the Governor, Throttle, and Linkages Work Together

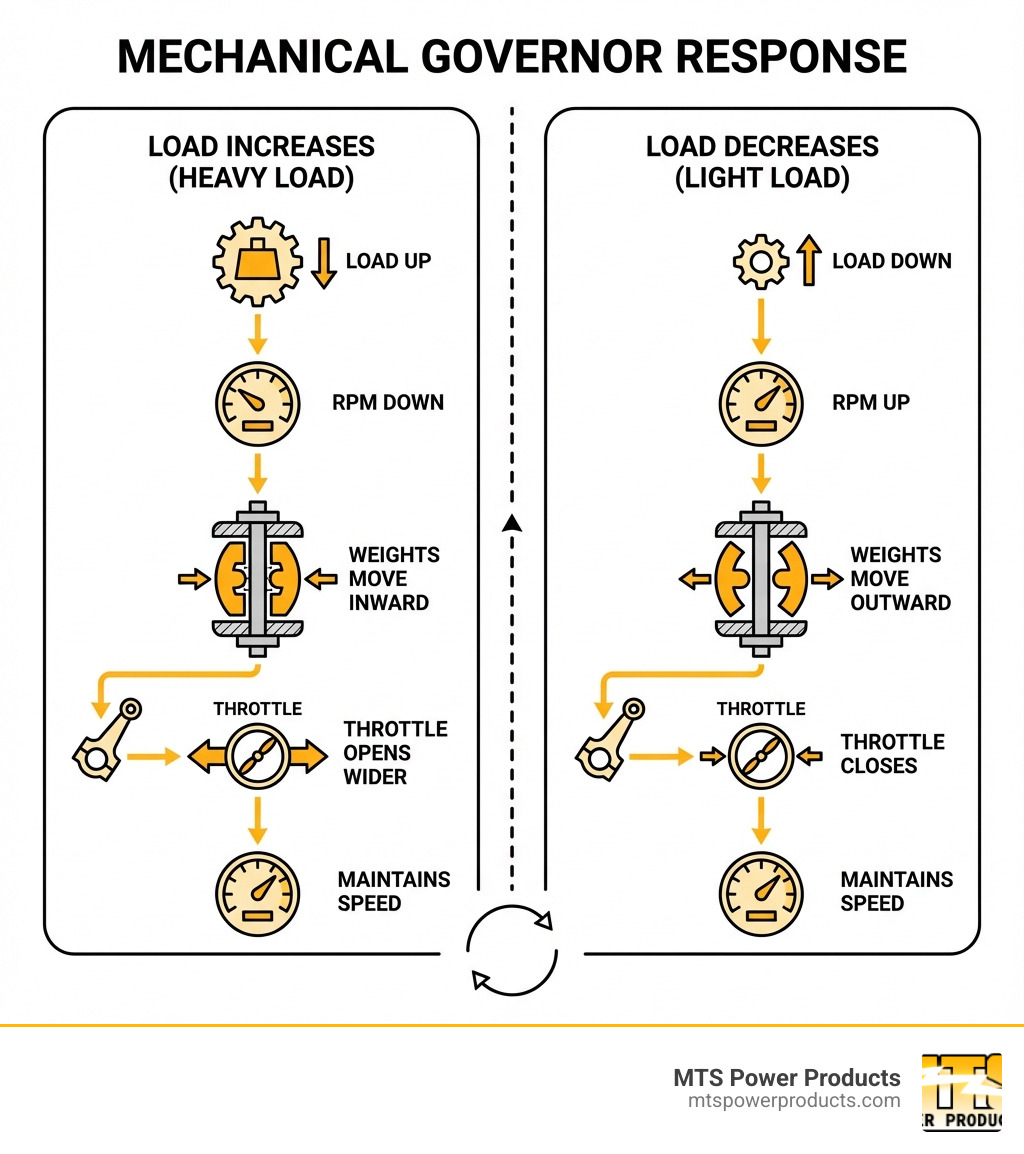

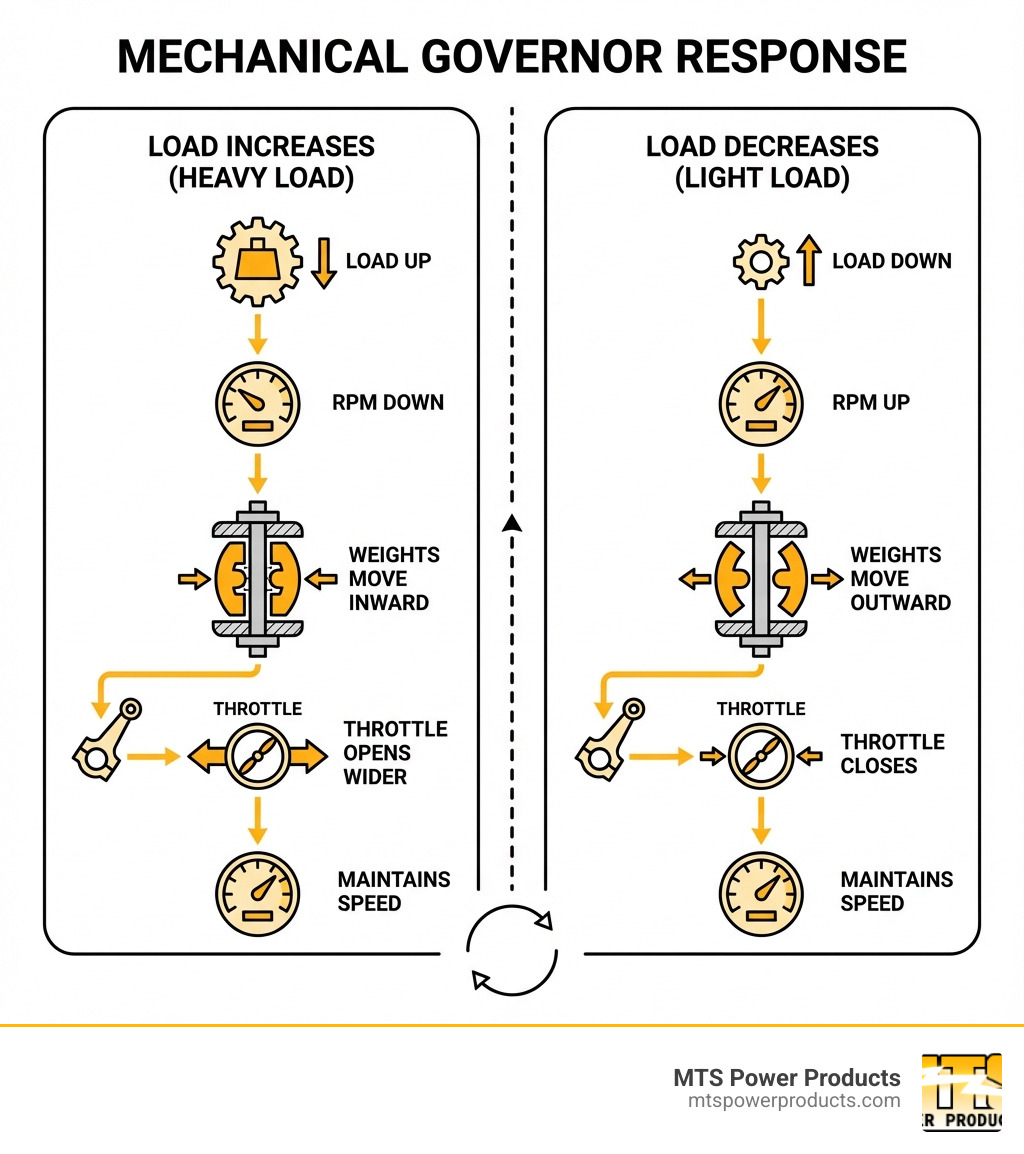

Understanding how the components work together is key to a proper adjustment. Most Tecumseh 4-cycle engines use a mechanical governor that operates on centrifugal force.

Here’s how the system works:

- The Governor Gear and Flyweights: Inside the crankcase, a gear driven by the camshaft spins a set of flyweights. Centrifugal force pushes them outward as engine speed increases.

- The Governor Spool: The flyweights push against a spool, causing it to move.

- The Governor Shaft and Lever: The spool’s movement is transferred outside the engine via a governor shaft, which is connected to the external governor lever (arm).

- The Throttle Linkage: The governor lever connects to the carburetor’s throttle plate via rods and springs.

- The Governor Spring: A spring pulls on the governor lever, trying to open the throttle. The tension on this spring determines the desired engine speed.

The Action:

It’s a continuous balancing act:

- Load Increases: RPM drops -> Centrifugal force decreases -> Flyweights move inward -> The governor spring pulls the lever, opening the throttle -> More fuel/air enters, and RPM increases back to the set speed.

- Load Decreases: RPM increases -> Centrifugal force increases -> Flyweights move outward -> They push against the lever, closing the throttle -> Engine speed is reduced, preventing over-revving.

The governor spring sets the desired speed, while the internal flyweights provide the control. For detailed schematics, we recommend checking Tecumseh service manuals for your specific engine model. You can often find Tecumseh service manuals here.

Before we dive into adjusting Tecumseh governor, let’s cover safety and tools. Safety is a non-negotiable rule when working with small engines.

First, always ensure the engine is off and cool. Never work on a hot engine. The most critical safety step is to disconnect the spark plug wire to prevent accidental starting. Secure the wire away from the spark plug so it can’t reconnect. Work in a well-ventilated area, especially for testing.

You won’t need a huge toolbox, but these items are key:

- Wrench or Socket Set: To loosen and tighten the governor arm’s clamp screw. The size varies by model.

- Screwdrivers: A flathead or Phillips head may be needed for access or minor adjustments.

- Pliers: Useful for manipulating linkages or springs.

- Digital Tachometer: While not required for the static adjustment, a tachometer is invaluable for verifying and fine-tuning the engine’s RPM. A simple inductive tachometer that wraps around the spark plug wire works well. You can find an example of a digital tachometer online.

- Safety Glasses: Protect your eyes from debris or springs.

- Work Gloves: Protect your hands from grease and sharp edges.

With these tools and precautions, you’re ready to adjust the governor.

The Step-by-Step Guide to Adjusting Tecumseh Governor

Now for the main event: the static adjustment. This is done with the engine off to synchronize the governor mechanism with the carburetor.

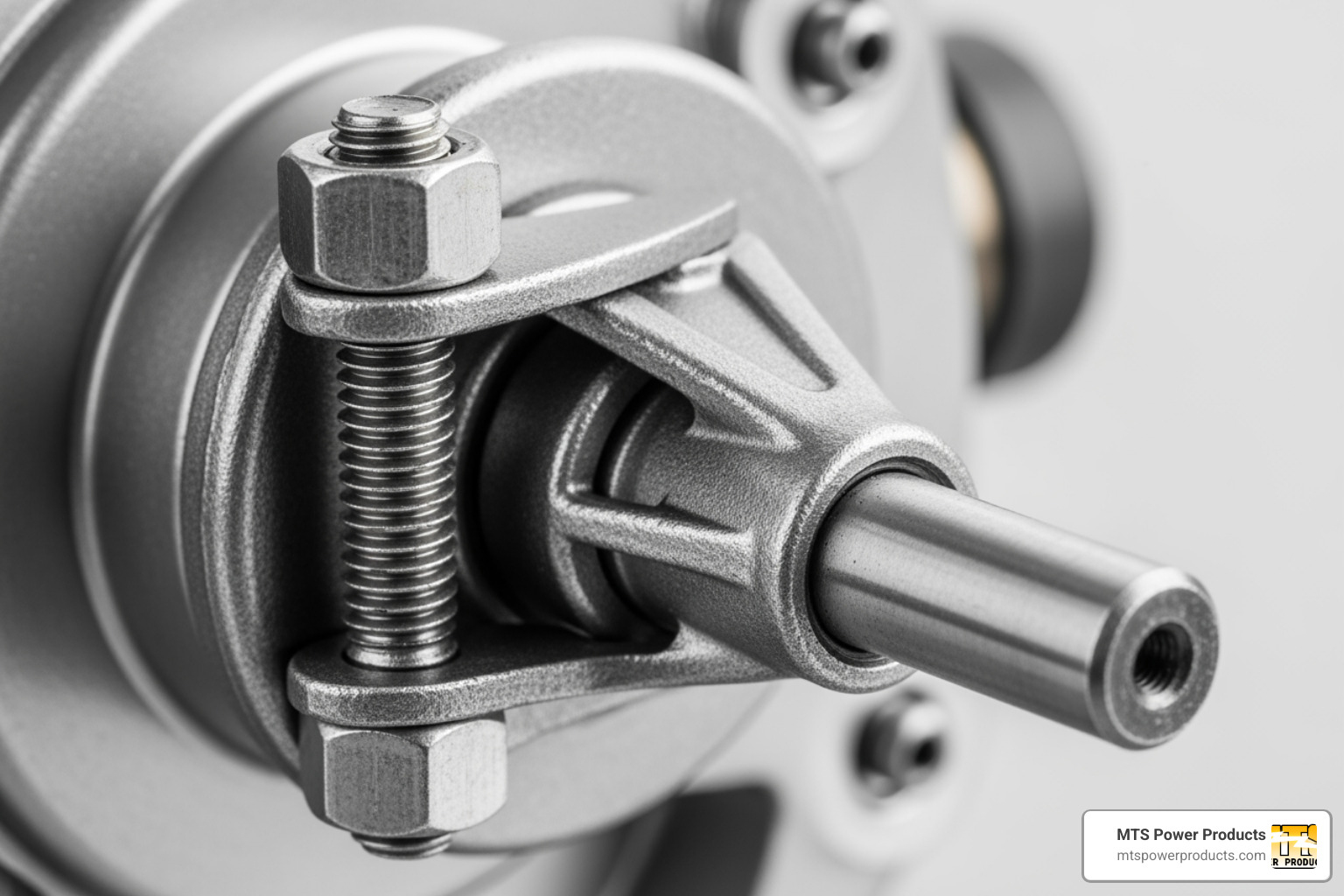

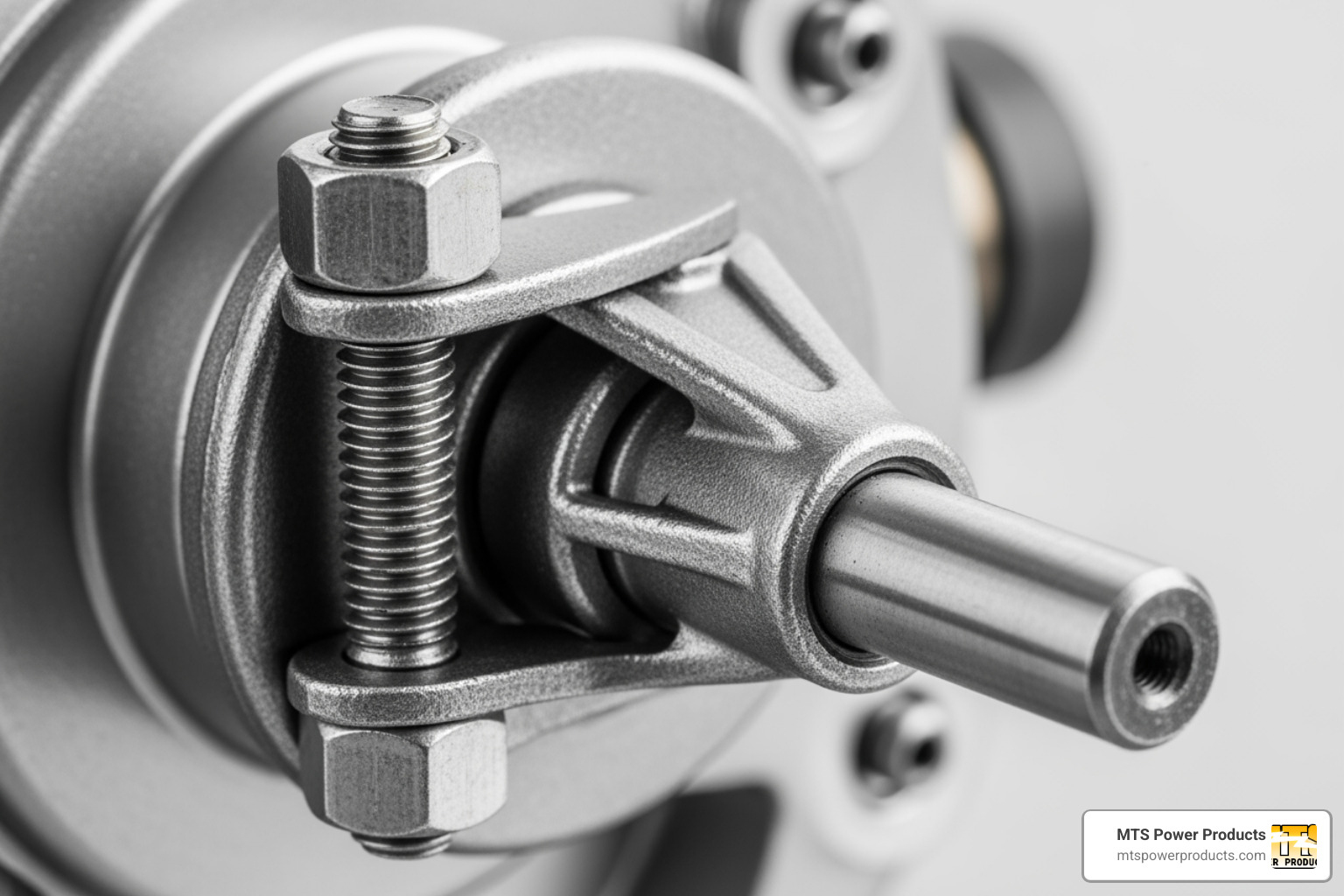

Locating the Governor Components

First, identify the key parts:

- Governor Arm/Lever: The external metal lever connected to the throttle linkage and governor shaft.

- Clamp Screw: The screw on the governor arm that clamps it to the shaft.

- Governor Shaft: The small shaft protruding from the engine block that the arm attaches to.

- Throttle Linkage: The rods and springs connecting the governor arm to the carburetor.

- Carburetor: You’ll be focused on its internal throttle plate (butterfly valve).

This core procedure ensures the governor has its full range of motion.

- Safety First: Ensure the engine is off and the spark plug wire is disconnected.

- Locate Components: Find the governor arm and the clamp screw that secures it to the governor shaft.

- Loosen the Clamp Screw: Use a wrench to loosen the screw just enough for the arm and shaft to move independently. Do not remove it.

- Set Wide Open Throttle (WOT): Manually push the carburetor’s throttle linkage to the fully open position and hold it there.

- Rotate the Governor Shaft: This is a critical step. While holding the throttle open:

- For Vertical Crankshaft Engines: Rotate the governor shaft counter-clockwise as far as it will go.

- For Horizontal Crankshaft Engines: Rotate the governor shaft clockwise as far as it will go.

- Tighten the Clamp Screw: Firmly hold both the throttle at WOT and the governor shaft at its limit, then tighten the clamp screw. This synchronizes the internal and external governor components.

- Release and Check: Release the throttle linkage. It should spring back to a nearly closed position.

Common Mistakes to Avoid During Adjustment

Avoiding these pitfalls will save you time and frustration:

- Not Holding Both Components Firmly: Failing to hold both the throttle at WOT and the governor shaft at its limit while tightening the screw will result in an incorrect setting.

- Incorrect Shaft Rotation Direction: Rotating the governor shaft in the wrong direction for your engine type (vertical vs. horizontal crankshaft) will cause an incorrect adjustment and erratic performance.

- Forgetting to Move Throttle to WOT: If the throttle isn’t fully open during the adjustment, the governor won’t have its full range of motion, resulting in a lack of power under load.

- Overtightening the Clamp Screw: Overtightening can strip threads or damage components. Tighten it to be snug, not excessive.

- Confusing Governor Issues with Carburetor Problems: Surging or poor performance can also be caused by a dirty or faulty carburetor. If a governor adjustment doesn’t fix the issue, inspect the carburetor. As one forum user noted, “If the governor adjustment doesn’t resolve the issue, it might be a carburetor problem.” Ensure the carb is clean, especially after recent maintenance.

After the Adjustment: Verification and Fine-Tuning

Once the static adjustment is done, it’s time to verify your work and fine-tune the engine’s speed. This involves starting the engine, warming it up, and using a tachometer to measure and adjust the RPM.

How to Verify and Fine-Tune Your Tecumseh Governor Adjustment

- Reconnect Spark Plug: Safely reattach the spark plug wire.

- Start and Warm Up: Start the engine and let it run for about five minutes at half throttle to reach normal operating temperature.

- Attach Tachometer: Attach a digital tachometer to the spark plug wire for an accurate RPM reading.

- Check High-Speed RPM: Move the throttle to the full-speed position (no load) and check the RPM.

- For generators, the target is typically 3600 RPM to ensure proper voltage and frequency.

- For lawnmowers and other equipment, the power band is often 2800-3200 RPM. Always check your owner’s manual for the exact specification.

- Adjust High Speed (if needed): Locate the high-speed adjustment screw or bendable tab on the governor linkage.

- To Increase RPM: Increase tension on the governor spring (turn screw clockwise or bend tab).

- To Decrease RPM: Decrease tension on the spring (turn screw counter-clockwise or bend tab).

Make small adjustments and re-check the RPM until you reach the target.

- Test Under Load: Engage the equipment (mower blades, generator load) to ensure the engine maintains a steady RPM. If it still bogs down or surges, further troubleshooting may be required.

The Dangers of an Improperly Set Governor

An improperly set governor can cause serious problems.

- Over-Revving (Engine “Running Away”): If set too high, the engine can race beyond its maximum designed RPM, causing catastrophic failure like thrown rods or a blown engine. This is extremely dangerous and requires an immediate shutdown.

- Underperformance and Damage from Overload: If set too low, the engine will bog down under load, leading to poor performance, inefficiency, and premature engine wear from the constant strain.

- Increased Fuel Consumption: An improperly set governor that causes hunting or inefficient operation will increase fuel consumption.

- Reduced Engine Longevity: Any erratic operation caused by a poor governor setting—over-revving, bogging, or hunting—will accelerate wear and shorten the engine’s lifespan.

Proper adjustment is about performance and protecting your investment.

Advanced Considerations and Troubleshooting

Sometimes, a static adjustment isn’t enough. If your engine still misbehaves after adjusting Tecumseh governor, it might be time to dig deeper.

Adjustment vs. Replacement: When is the Governor Faulty?

How do you know if the governor needs adjustment or replacement? Look for signs of internal failure.

Signs of Internal Governor Failure (Requiring Replacement):

- Engine “Runs Away” Uncontrollably: If the engine immediately races to maximum RPM and external adjustments have no effect, an internal component has likely failed.

- Linkage Disconnected Test: A key diagnostic test: with the engine off, disconnect the throttle linkage from the governor arm. If the arm moves freely with no resistance, the internal mechanism is likely broken. A healthy governor will have some spring-like resistance.

- Broken Plastic Spool or Worn Governor Gear: Internal plastic parts like the governor spool and gear can become brittle and break. A broken spool is a common cause of a runaway engine. If you suspect internal failure, external adjustments won’t work. The repair requires opening the crankcase to replace the broken parts, which may be a job for a mechanic. A detailed guide on governor repair can illustrate these internal issues.

If you suspect internal governor failure, external adjustment is futile. It’s time for a repair that involves opening the engine’s crankcase to access and replace the faulty internal components. This is a more involved repair, often best left to experienced mechanics if you’re not comfortable with engine disassembly.

Are All Tecumseh Governor Adjustments the Same?

While the general principle of adjusting Tecumseh governor is consistent, there are differences across models.

- Mechanical vs. Pneumatic (Air Vane) Governors: This guide focuses on the common mechanical (flyweight) governor in 4-cycle engines. Some 2-cycle models use a pneumatic (air vane) governor, which is adjusted differently and requires consulting the specific service manual.

- Engine Model and Application Differences:

- RPM Targets: Target RPMs vary by application. A generator needs a precise 3600 RPM, while a mower may run closer to 3200 RPM. Always check your manual.

- Linkage and Control Design: The layout of linkages, springs, and adjustment points can differ between engine models.

- Idle Speed Adjustment: Some models have a separate, non-governed idle speed screw on the carburetor that may also need adjustment.

- Checking Specific Engine Manuals: Due to these variations, it is crucial to consult the specific service manual for your Tecumseh engine model for detailed diagrams and instructions.

Remember to verify the specifics for your engine to ensure a perfect adjustment.

Conclusion

Mastering the skill of adjusting Tecumseh governor empowers you to maintain your small engine’s performance and longevity. By following the steps outlined—from the initial static adjustment to fine-tuning with a tachometer—you can resolve common issues like surging, bogging, and over-revving. This simple procedure ensures your equipment operates safely and efficiently, whether it’s a generator needing a steady 3600 RPM or a lawnmower requiring consistent power.

Proper governor maintenance is a key investment in your equipment’s reliability. However, if an adjustment doesn’t solve the problem, it may point to an internal failure requiring replacement parts.

At MTS Power Products, we understand the importance of precise engine control for reliable power. Based in Miami, Florida, with worldwide delivery, we are a direct source for professional-quality generator sets, automatic transfer switches, and our own line of McPherson Controls. Our products, including high-quality governors, feature advanced programmable displays and safety mechanisms for superior control. For all your power product needs, from individual components to complete generator solutions, we’re here to help.

Explore our selection of high-quality governors and controls