Why Your Backup Generator Needs a Brain

An automatic transfer switch (ATS) is the intelligent device that automatically switches your electrical load between your utility power and backup generator when the power goes out—and switches back when utility power returns.

What an Automatic Transfer Switch Does:

- Monitors your utility power constantly for voltage drops or failures

- Starts your backup generator automatically when it detects an outage

- Transfers your electrical load from utility to generator power seamlessly

- Switches back to utility power when it’s restored

- Shuts down your generator safely after a cool-down period

Think of it this way: your generator is the muscle, but the ATS is the brain that makes everything work without you lifting a finger.

Benjamin Franklin once said, “An ounce of prevention is worth a pound of cure.” He wasn’t talking about backup power, but he might as well have been. For facilities managers like John who can’t afford downtime, or homeowners like Rebecca preparing for hurricane season in South Florida, an ATS transforms a backup generator from a manual hassle into a true automatic safety net.

The global automatic transfer switch market is growing fast—from $1.5 billion in 2022 to a projected $2.3 billion by 2030. That growth isn’t random. It’s driven by people who’ve learned the hard way that when the power goes out, you want a system that works automatically, safely, and reliably.

Without an ATS, your generator is just an expensive lawn ornament during an outage. With one, you get seamless, safe, automatic protection for your home, your family, or your business operations.

The Unsung Hero of Uninterrupted Power

What is an Automatic Transfer Switch (ATS)?

At its core, an automatic transfer switch (ATS) is an electrical switch that neatly manages the power supply to your home or business. It’s a self-acting, intelligent device governed by dedicated control logic, designed to ensure a continuous flow of electricity. Its main job is to switch your electrical load between two primary sources: your utility power (the grid) and an alternate power source, typically a backup generator.

We often call the ATS the “brain” of your backup power system because it constantly monitors your utility power. The moment it detects a disruption—whether it’s a complete outage or a significant voltage drop—it springs into action. This seamless switching ensures that essential systems, from your refrigerator to critical industrial machinery, remain powered without manual intervention.

Why is an ATS Essential for Your Backup System?

The benefits of integrating an ATS into your power system are numerous, touching upon safety, convenience, and reliability.

- Best Safety: Perhaps the most critical role of an ATS is safety. It automatically isolates your backup generator from the utility grid, preventing a dangerous condition known as “backfeeding.” Backfeeding occurs when your generator sends power back into the utility lines, posing a severe electrocution risk to utility workers who might be repairing the grid. The ATS ensures this never happens, keeping everyone safe.

- Ultimate Convenience: Imagine a power outage hitting in the middle of the night. With an ATS, you don’t have to stumble around in the dark, drag out a portable generator, or fumble with extension cords. The ATS automatically detects the outage, starts your generator, and transfers power, all within seconds. When utility power returns, it switches back and shuts down the generator. It’s truly “set it and forget it” power.

- Reliable, Continuous Power: For homes, this means your heating, cooling, refrigeration, and security systems remain operational, protecting your family and preventing food spoilage. For businesses, especially in critical sectors like data centers, healthcare, or manufacturing, the ATS is vital for continuous operation. The average cost of power outage downtime for businesses can be staggering, reaching up to $9,000 per minute, making an ATS an invaluable investment.

- Protecting Electronics: Modern electronics are sensitive to sudden power interruptions and fluctuations. A properly configured ATS ensures a smooth transition between power sources, safeguarding your valuable equipment from potential damage.

- Business Continuity: In today’s interconnected world, even a brief power loss can halt operations, lead to data loss, and damage reputation. An ATS ensures that critical business functions continue uninterrupted, minimizing financial losses and maintaining productivity. The increasing demand for reliable backup solutions across residential, commercial, and industrial sectors, alongside the growth of renewable energy and smart grid technologies, is fueling the impressive growth of the ATS market globally. North America, for instance, held the largest market share in 2022, driven by the prevalence of power outages and the adoption of backup systems.

How an Automatic Transfer Switch Works: The Core Mechanics

The magic of an automatic transfer switch lies in its sophisticated yet straightforward operation. At its heart is a control logic system, typically microprocessor-based, that acts as the vigilant guardian of your power supply. This controller constantly monitors the electrical parameters of your primary (utility) and alternate (generator) power sources, looking for any deviations in voltage or frequency.

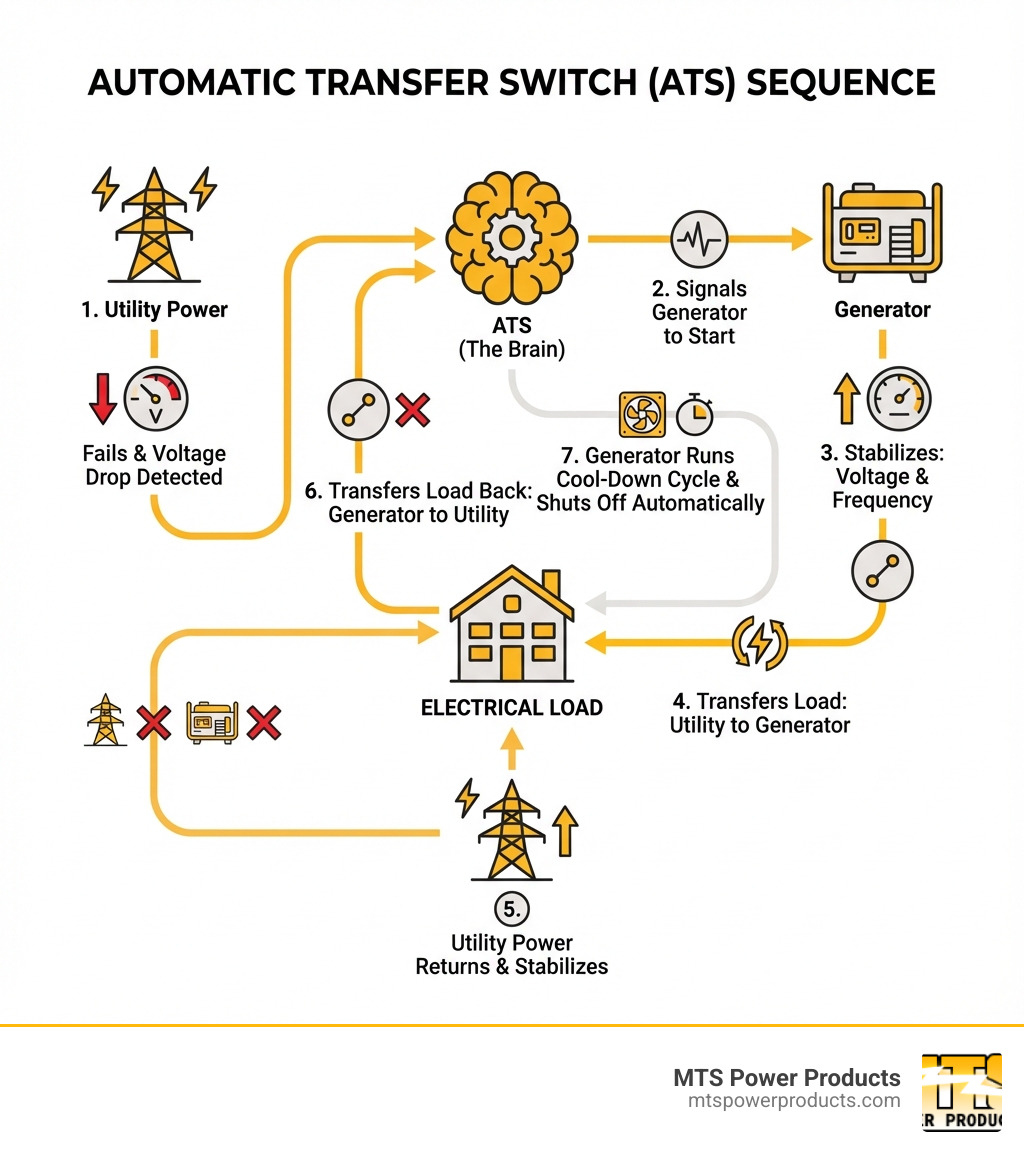

The Automatic Transfer Sequence

When the ATS detects an issue, it initiates a precise sequence of events to ensure your power remains uninterrupted. Here’s a typical transfer sequence:

- Utility Power Fails: The ATS continuously monitors the incoming utility power. If it detects a voltage drop below a preset threshold (e.g., 80% of nominal) or a complete outage, it signals a power disruption.

- ATS Signals Generator to Start: After a brief delay (Time Delay Engine Start, or TDES), the ATS sends a signal to your backup generator, commanding it to start. This delay prevents the generator from starting due to momentary flickers or brownouts.

- Generator Stabilizes: The generator starts and runs up to its operating speed, producing electricity. The ATS monitors the generator’s output, ensuring its voltage and frequency are stable and within acceptable parameters (e.g., 240-246 VAC and 60-62 Hz for no-load).

- ATS Transfers Load to Generator: Once the generator’s power is stable and after another short delay (Time Delay Normal to Emergency, or TDNE), the ATS physically switches the electrical load from the utility connection to the generator’s power output. This is the moment your home or business begins running on backup power. You can learn more about how this process works in detail by exploring our resources on Helpful Info On Generator Transfer Switch Options.

- Utility Power Returns: The ATS continues to monitor the utility power. When it detects that the utility supply has been restored and is stable for a predetermined period, it prepares to switch back.

- ATS Transfers Load Back to Utility: After another delay (Time Delay Emergency to Normal, or TDEN), the ATS switches the electrical load back to the utility power source.

- Generator Cools Down and Shuts Off: With the load now on utility power, the ATS signals the generator to enter a cool-down period. This allows the generator engine to gradually cool down without load, extending its lifespan. After the cool-down (Time Delay Engine Cool-down, or TDEC), the generator shuts off.

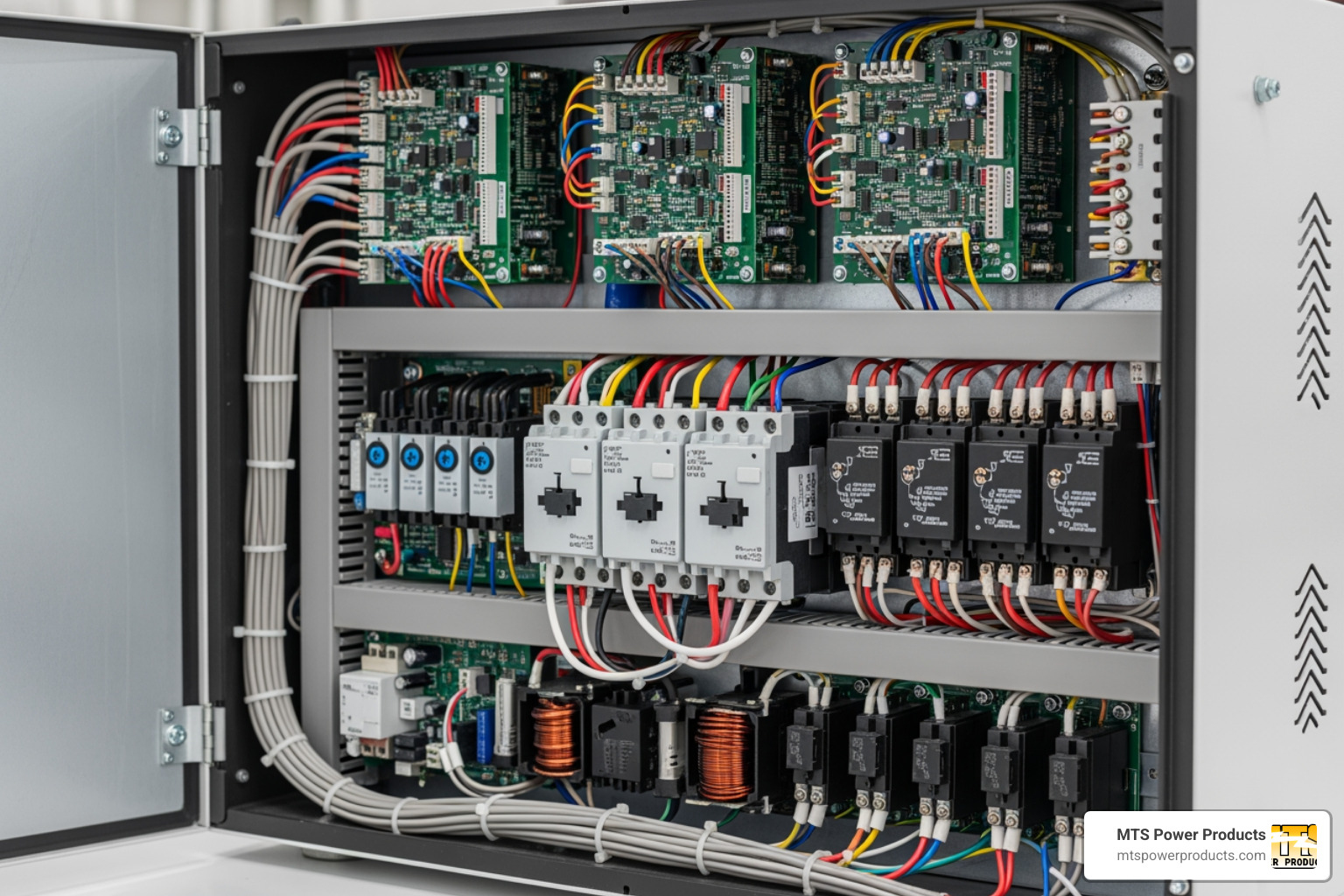

Key Components and Controls

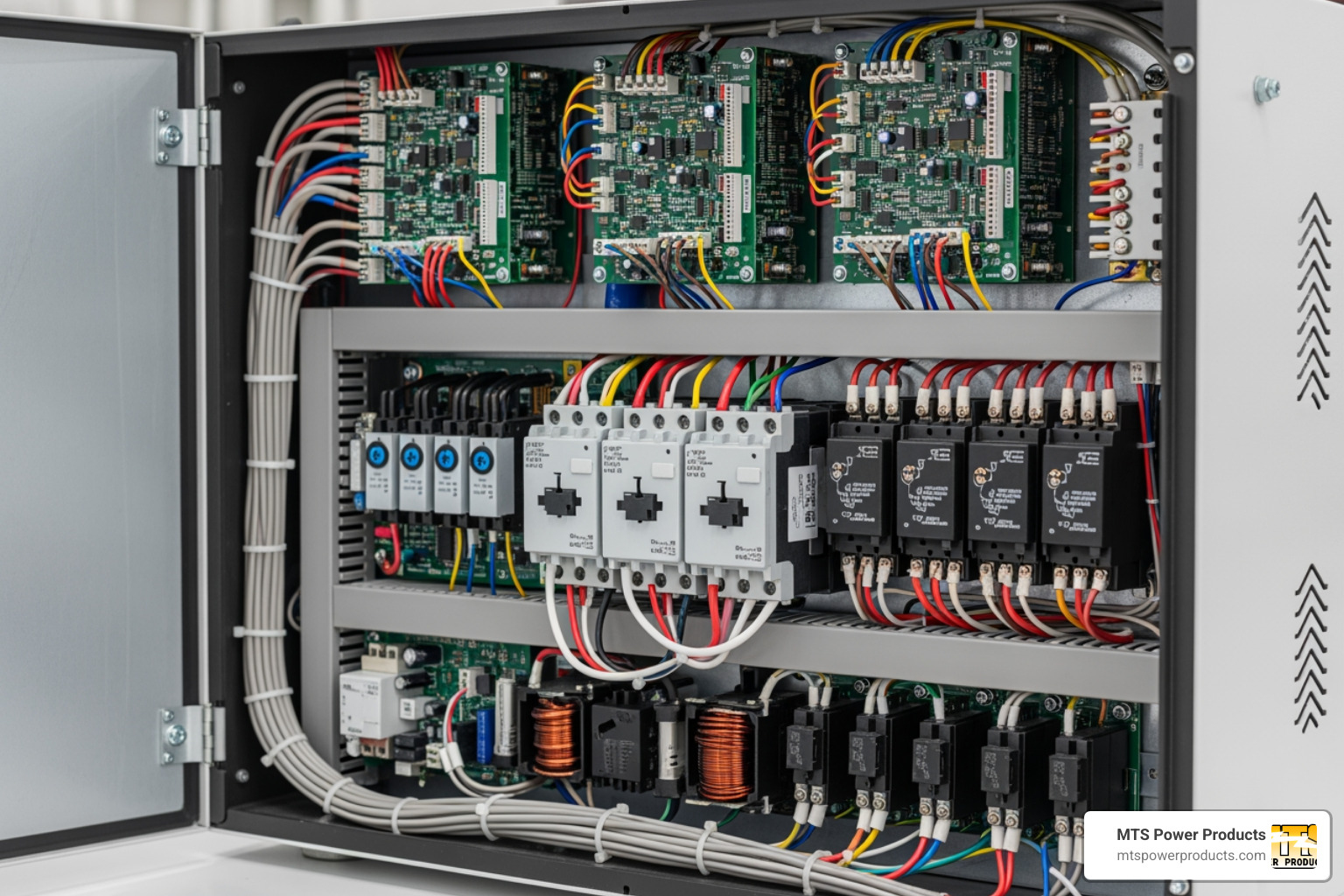

An ATS is more than just a switch; it’s a sophisticated system with several crucial components:

- Switching Mechanism: This is the physical component that makes or breaks the electrical connections. We’ll dive into the different types shortly, but whether it’s a contactor, molded case, or power frame type, its job is to reliably move the electrical load.

- ATS Controller: This is the “brain” itself. Our McPherson Controls line features advanced ATS controllers that are microprocessor-based, constantly monitoring utility and generator parameters. These controllers can be programmed with various time delays and setpoints to perfectly tailor the transfer sequence to your needs. They also offer features like programmable displays and remote monitoring for improved control and safety. You can explore our range of ATS Controller options.

- Terminal Lugs: These are the connection points for your electrical wiring. Proper installation dictates that all conductors must be tightened to factory-specified torque values to ensure secure and safe connections.

- Enclosure: The entire ATS assembly is housed within a protective enclosure. For outdoor installations, we often recommend NEMA 3R rated enclosures, which provide protection against falling rain, sleet, and external ice formation, perfect for the varied weather conditions in Miami, FL.

Understanding these components and their functions highlights why the ATS is so integral to a reliable backup power system. For more detailed information on configuring and managing these critical components, check out our resources on Automatic Transfer Switch Controls.

Understanding ATS Types, Modes, and Arrangements

When it comes to maintaining power continuity, not all automatic transfer switches are created equal. They come in various types, modes, and arrangements, each designed to meet specific power system design needs, improve redundancy, and bolster system reliability. To help you steer these options, we’ve put together a comprehensive Automatic Transfer Switch Guide.

Transition Modes: Open vs. Closed

The way an ATS transfers power significantly impacts how noticeable the power interruption is to your connected loads. There are two primary transition modes:

- Open Transition (Break-Before-Make): This is the most common and economical type. In an open transition, the ATS breaks the connection to one power source (e.g., utility) before making the connection to the other (e.g., generator). This results in a momentary power interruption, typically lasting milliseconds to a few seconds, during which your load is without power. For many residential and commercial applications, this brief interruption is acceptable. Open transition transfer switches are also known as break-before-make switches.

- Closed Transition (Make-Before-Break): For critical applications where even a momentary power interruption is unacceptable (such as data centers, hospitals, or sensitive manufacturing processes), a closed transition ATS is often preferred. These switches briefly connect both power sources in parallel before disconnecting the original source. This “make-before-break” action ensures a virtually seamless transfer with zero power interruption. However, closed transition transfers are more complex, requiring precise synchronization parameters between the two power sources. These parameters typically include:

- Voltage difference less than 5%

- Frequency difference less than 0.2 Hz

- Phase angle between sources of 5 degrees or less

The overlap time for a closed transition is generally less than 100 milliseconds. This capability is also useful for “soft loading” or “peak shaving,” where a generator can run in parallel with the utility to reduce demand charges.

Here’s a quick comparison:

| Feature |

Open Transition (Break-Before-Make) |

Closed Transition (Make-Before-Break) |

| Power Interruption |

Momentary (milliseconds to seconds) |

None (virtually seamless) |

| Complexity |

Simpler, more common |

More complex, requires synchronization |

| Cost |

Generally lower |

Higher |

| Applications |

Residential, most commercial, loads tolerant of brief outages |

Data centers, hospitals, critical industrial processes, sensitive electronics |

| Synchronization Req. |

None |

Yes (voltage, frequency, phase angle matching) |

| Utility Approval |

Not typically required |

Often required for paralleling with the grid |

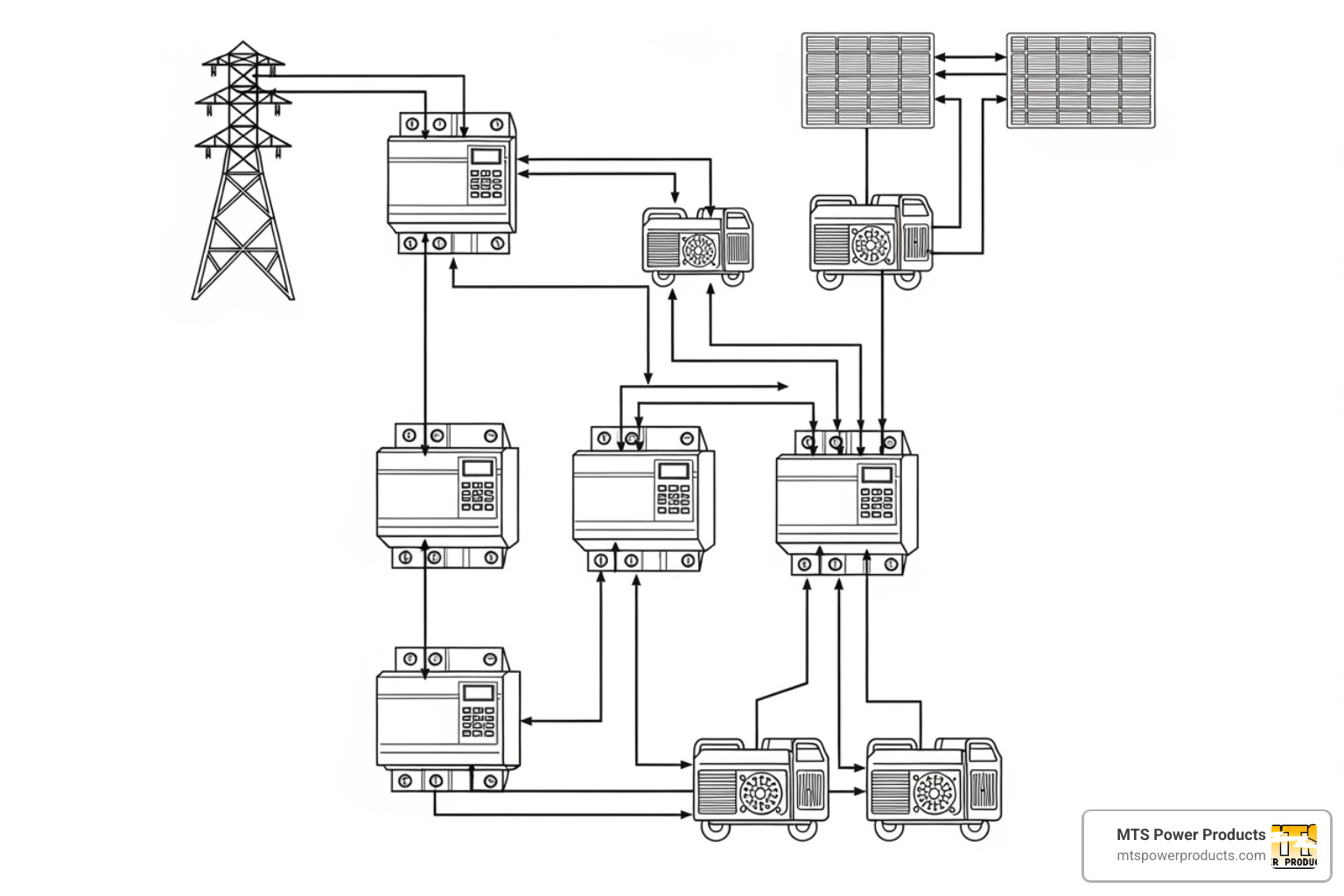

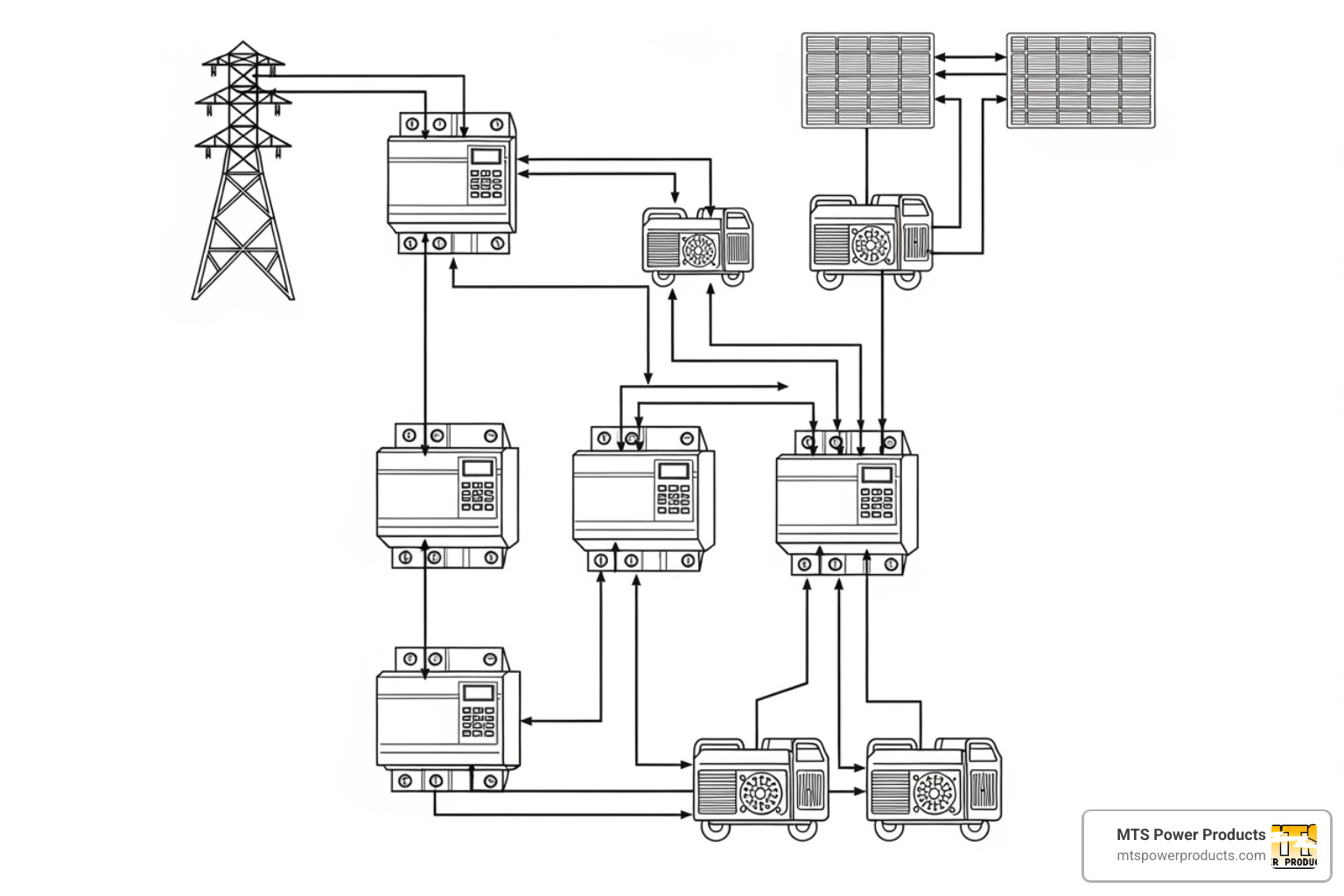

Common ATS Arrangements

The configuration of your power sources dictates the type of ATS arrangement you’ll need:

- Utility-Generator: This is the most common arrangement, used with a single utility connection and a single backup generator. When utility power fails, the ATS switches to the generator. This is ideal for most homes and many businesses in Miami.

- Utility-Utility: This arrangement provides redundancy by allowing a facility to draw power from two separate utility feeds. If one utility line goes down, the ATS switches to the other. This is often seen in critical commercial settings.

- Generator-Generator: Less common, this setup is used in remote installations where two generator sets provide prime power. If one generator fails or needs maintenance, the ATS switches to the other.

- Three-Source Arrangements: For even greater redundancy, complex systems might use three sources, such as Utility—Generator—Generator or Utility—Utility—Generator. These are designed for facilities with extremely high uptime requirements, offering multiple layers of backup.

Our solutions, including our McPherson Controls line, are designed to integrate seamlessly into any of these arrangements. Whether you need a simple utility-generator setup for your home or a complex multi-source system for a commercial operation, we can help. For more specific configurations, consider our Generator Automatic Transfer Switch options.

Modes of Operation and Switching Mechanisms

Beyond transition types, ATS units also vary in how they can be operated and the physical mechanisms they use to switch power:

- Modes of Operation:

- Manual: Transfer is initiated and operated entirely by hand. While some ATS units have a manual override, fully manual transfer switches require human intervention for every step.

- Non-automatic: A manual initiation by an operator causes the electromechanical operation of the switch. This means someone presses a button, but the switch itself moves automatically.

- Automatic: The most common and convenient mode for an ATS. The controller is self-acting, constantly monitoring power sources and managing the entire transfer sequence without human intervention.

- Common Switching Mechanisms:

- Contactor Type: These are robust switches that use electrically operated contacts to transfer power. They are designed to quickly and reliably transition critical loads and are ideal for various applications, including NFPA 70 emergency, legally required, optional standby, and critical operations systems. We offer contactor type switches that provide excellent performance. You can see how these switches are designed for quick and reliable transitions by exploring resources like View full screen Eaton’s contactor type transfer switches.

- Molded Case Type: These switches integrate the transfer mechanism within a molded case circuit breaker frame. They offer good short-circuit withstand ratings and are often used in commercial and industrial applications.

- Power Frame Type: Designed for very high current applications, these are heavy-duty switches built for extreme durability and high fault current withstand capabilities, typically found in large industrial or utility-scale installations.

Selecting the Right ATS: From Home to Industry

Choosing the correct automatic transfer switch is crucial for the optimal performance and safety of your backup power system. It’s not a one-size-fits-all decision; your selection will depend heavily on your application-specific needs, the size of your generator, and adherence to safety standards. To help you get started, we have resources like our Generator Transfer Switch Kit What To Know.

ATS Applications: Residential, Commercial, and Industrial

The versatility of ATS technology means there’s a solution for nearly every power need:

- Residential Use: For homeowners in Miami, FL, a residential ATS paired with a home standby generator ensures comfort and security during power outages. It keeps your lights on, your air conditioning running, your food refrigerated, and your security systems active. The residential segment is seeing significant growth, driven by the increasing need for uninterrupted power supply.

- Commercial Buildings: From small businesses to large office complexes, commercial ATS units protect critical operations. They’re essential for maintaining lighting, HVAC, point-of-sale systems, and communication networks, preventing costly downtime.

- Industrial Facilities: In manufacturing plants, data centers, and other industrial settings, continuous power is non-negotiable. An industrial ATS protects sensitive machinery, prevents data loss, and ensures the safety of operations. These applications often require more robust ATS units with higher amperage ratings and advanced features. The industrial segment is expected to witness substantial growth due to this critical need. We offer a wide range of products for diverse applications; you can find more options when you Shop Generator Automatic Transfer Switches from General Power.

Key Features to Consider When Purchasing an automatic transfer switch

When you’re ready to invest in an ATS, consider these vital features:

- Amperage Rating: This is perhaps the most critical specification. The ATS amperage should match or exceed the main breaker amperage of your electrical panel if you want to back up your entire home or facility. For load center transfer switches (which power only essential circuits), the amperage should be sized to the total load of those selected circuits. Our range includes switches from 50 amps up to 2,000 amps and beyond, ensuring we have a solution for every scale, such as our 200 Amp 2 Pole Automatic Transfer Switch UL Listed.

- Voltage Rating: Ensure the ATS’s voltage rating matches your electrical system (e.g., 120V, 208V, 240V, 480V, 600V). We provide options for various AC system voltage ratings, including 120/240 Single-Phase and 277/480 Three-Phase systems, common in Miami.

- NEMA Enclosure Types: The National Electrical Manufacturers Association (NEMA) defines standards for enclosures, crucial for protecting the ATS from environmental factors.

- NEMA 1: Suitable for indoor use, providing protection against incidental contact.

- NEMA 3R: Essential for outdoor installations, protecting against rain, sleet, external ice formation, and dust. This is a popular choice for outdoor generator setups in South Florida.

- Service Entrance Rated: An ATS can be “service entrance rated,” meaning it includes a built-in main service disconnect breaker. This allows the ATS to be installed where the utility service enters your building, simplifying wiring and often reducing installation costs. If an ATS is not service entrance rated, a separate service disconnect must be installed.

- Withstand Closing Current Rating (WCR): This rating indicates the maximum fault current an ATS can safely withstand and interrupt without sustaining damage. It’s a critical safety feature, especially in industrial applications, ensuring system integrity and reliability during a short circuit.

Safety, Installation, and Maintenance

The safe and effective operation of an ATS hinges on proper installation and ongoing maintenance:

- Professional Installation: Due to the complexity and inherent dangers of working with high-voltage electricity, an ATS must always be installed by competent, qualified personnel, such as a licensed electrician. Adhering to local, state, and national electrical and building codes is paramount.

- Code Compliance: We always ensure our products meet stringent safety and performance standards. In the U.S., the National Electrical Code (NEC) and NFPA 110 (Standard for Emergency and Standby Power Systems) provide guidelines for ATS installation and operation, mandating features like proper isolation of power sources.

- Preventing Backfeed: A core safety principle is to always isolate the backup generator from the electric utility when it’s operating. This prevents backfeeding, protecting utility workers and your equipment. The ATS performs this critical function automatically.

- Regular Testing and Maintenance: Like any critical electrical component, an ATS requires periodic testing and maintenance. This includes code-mandated monthly testing for many commercial applications. Regular checks ensure the system will perform as expected when an actual outage occurs. Our McPherson Controls ATS units are designed for reliability and ease of maintenance, and we provide comprehensive support. You can find essential safety guidelines for your generator and transfer switch by consulting resources like Safely Installing Your Standby Electric Generator or exploring our general Generator Transfer Switch information.

Advanced Concepts and Comparisons

As power needs evolve, so does the technology behind automatic transfer switches. Beyond the basic function of switching power, advanced ATS units offer sophisticated power quality management and specialized capabilities. For a deeper dive into these topics, we recommend reading our article, Power Shift All You Need To Know About Automatic Transfer Switches.

How does an automatic transfer switch differ from a manual transfer switch?

While both automatic and manual transfer switches achieve the goal of connecting a load to an alternate power source, their methods and implications are vastly different:

| Feature |

Automatic Transfer Switch (ATS) |

Manual Transfer Switch (MTS) |

| Operation |

Fully automatic; detects outage, starts generator, transfers load |

Manual; requires human intervention to start generator and operate switch |

| Human Intervention |

None required |

Essential for every step |

| Speed of Transfer |

Seconds (after generator stabilizes) |

Minutes to hours (depending on human response and setup) |

| Safety |

Automatically prevents backfeeding |

Relies on careful human operation to prevent backfeeding |

| Convenience |

High; “set it and forget it” |

Low; requires effort during an outage |

| Cost |

Higher initial investment |

Lower initial investment |

| Best Use Cases |

Critical loads, homes, businesses, data centers, hospitals |

Non-critical loads, temporary power needs, budget-conscious users |

The primary advantage of an ATS is its seamless, hands-free operation, which is critical for ensuring continuous power supply and safety. A manual transfer switch, while less expensive, requires human presence and action, making it unsuitable for applications where continuous power is vital or when no one is available to operate it.

Understanding Soft Loading and Static Transfer Switches (STS)

Two advanced concepts in transfer switches are gaining increasing importance for specific applications:

- Soft Loading Transfer Switch (SLTS): Also known as a Closed Transition Soft Load Transfer Switch, an SLTS allows a generator to be synchronized and run in parallel with the utility grid for a brief period during a transfer. This capability is used not only for seamless (closed) transfers but also for “peak shaving.” Peak shaving involves running the generator during periods of high utility demand (and thus high electricity rates) to reduce the facility’s overall demand from the grid, leading to significant cost savings. The ASCO Series 7000 Soft Load Power Transfer Switches are a prominent example of this technology.

- Static Transfer Switch (STS): Unlike mechanical ATS units with moving parts, a static transfer switch uses power semiconductors, such as Silicon-Controlled Rectifiers (SCRs), to transfer electrical loads between two synchronized AC power sources. The key advantage of an STS is its incredibly fast transfer speed—often within a quarter-cycle of the power frequency (typically 2-4 milliseconds). This ultra-fast, non-mechanical transfer makes STSs ideal for extremely sensitive electronic equipment that cannot tolerate even the briefest interruption, such as in data centers or telecommunications facilities. While a mechanical ATS might take seconds, an STS performs the switch in milliseconds. You can learn more about this cutting-edge technology by exploring resources like “Static Transfer Switch (eSTS) | LayerZero Power Systems Transfer Switch”.

Your Partner in Power Continuity

In a world increasingly reliant on uninterrupted power, the automatic transfer switch stands out as a critical component of any reliable backup power system. It’s the intelligent guardian that ensures seamless power transition, improves safety, and provides peace of mind, whether for your home or your business.

At MTS Power Products, we pride ourselves on being a leading manufacturer and provider of generator sets, generator parts, and, of course, automatic transfer switches. Based right here in Miami, Florida, we understand the unique power challenges faced by our community and offer professional-quality solutions. Our McPherson Controls line features custom-engineered power controls with advanced features like programmable displays and remote monitoring, all built to the highest safety standards.

We are your direct source for professional quality generators, control panels, voltage regulators, and much more. With worldwide delivery from our centrally located facility near Miami International Airport and the Port of Miami, we are uniquely positioned to meet your power continuity needs.

Don’t let power outages disrupt your life or business. Invest in the brain behind your backup. Explore our full range of Automatic Transfer Switches today and let us help you find the perfect solution for continuous, reliable power.