Buy Direct

from the Manufacturer

Sell our Products

Become a Distributor

Discounts

on volume purchases

Visit Us

at our Miami office

from the Manufacturer

Become a Distributor

on volume purchases

at our Miami office

Automatic generator control (AGC) is a system that continuously adjusts the power output of generators to match electricity demand. Its key functions are to balance generation with load, maintain stable system frequency (typically 60 Hz in the US), manage power flow between regions, and optimize costs. By making adjustments within seconds, AGC prevents frequency deviations that could lead to blackouts.

Whether you’re managing a manufacturing facility that can’t afford downtime or protecting your home during hurricane season, understanding how power systems maintain stability is crucial. The electrical grid requires generation and load to balance moment by moment. If generation exceeds demand, system frequency rises; if demand exceeds generation, frequency drops. Both scenarios threaten grid stability.

Before automatic systems, operators manually adjusted a single “regulating unit” to maintain this balance. Modern AGC systems allow multiple generators to participate, reducing wear on individual units while improving overall efficiency and economy. This is especially important today, as grids face new challenges from renewable energy integration and aging infrastructure. With more than half of all U.S. generating units over 30 years old, regular system tuning is essential for maintaining performance.

Basic automatic generator control glossary:

Imagine trying to balance a seesaw with weights constantly being added and removed. That’s what our power grid faces every second. Automatic Generation Control (AGC) is the system that keeps everything balanced, ensuring the electricity flowing into the grid perfectly matches what we’re using.

Its primary objective is to maintain the delicate balance between electricity generation and consumption. When you flip on a light switch, AGC is already making adjustments to handle that new demand. This matters because our grid operates at a specific frequency—60 Hz in the United States. If generation exceeds use, the frequency climbs; if demand outpaces generation, it drops. Either scenario can damage equipment and lead to widespread blackouts.

In the early days of power systems, operators handled everything manually, watching dials and adjusting a single “regulating unit” to match demand. This approach was slow, prone to human error, and placed immense wear and tear on the regulating generator.

The development of AGC was transformative. Automatic systems allowed multiple generating units to participate in regulation simultaneously. Instead of one overworked generator, the burden could be distributed, dramatically improving grid reliability and efficiency.

Modern AGC delivers benefits that ripple through the entire power system. It improves efficiency by coordinating generators to ensure the most economical units run first, minimizing fuel consumption. It ensures system stability by acting as the grid’s first line of defense against frequency deviations. It also enables economic operation by managing power interchange over tie lines connecting different control areas, which is essential for regional power trading.

Perhaps most importantly, AGC delivers reduced equipment wear. By distributing the regulation burden, the system prevents any single unit from being overworked, leading to less mechanical stress, lower maintenance costs, and longer equipment life. As our energy landscape grows more complex with aging infrastructure—over half of U.S. generating units are over 30 years old—the role of AGC is more critical than ever.

For a deeper dive into the engineering principles behind these systems, you can explore resources like Engineering:Automatic generation control – HandWiki.

Think of the electrical grid as a living organism that needs constant care. As demand shifts throughout the day, automatic generator control keeps everything balanced through thousands of tiny, unnoticeable adjustments.

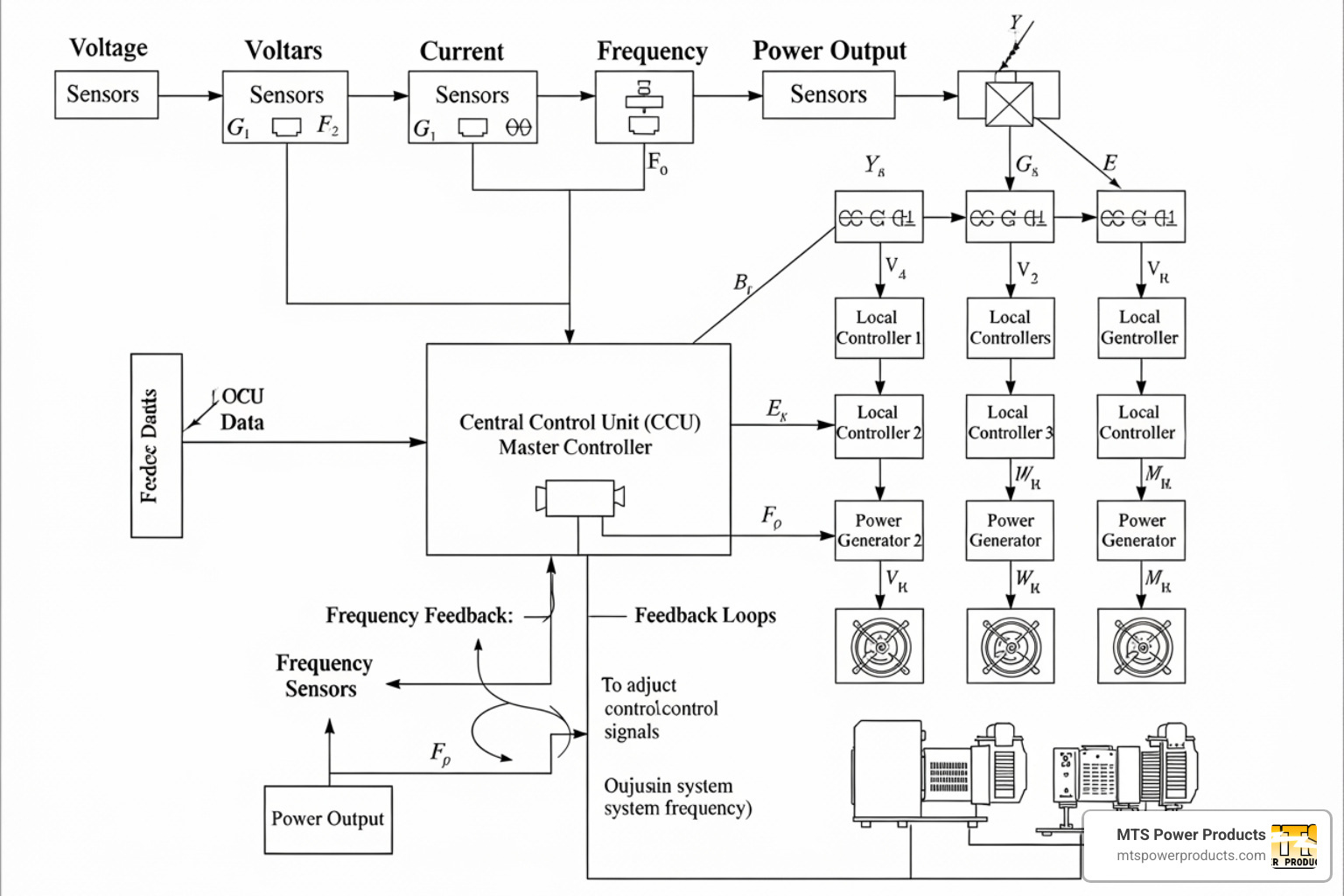

At the heart of this system is the Area Control Error (ACE), which measures the imbalance between generation and demand, including scheduled power flows between regions. The entire job of AGC is to drive the ACE value back to zero. This is achieved through control loops that manage both real power balance (affecting frequency) and reactive power balance (affecting voltage).

An automatic generator control system integrates several critical components:

Load Frequency Control (LFC) is the mechanism that keeps electricity at exactly 60 Hz. It operates on three levels:

This entire process is aided by grid inertia, the kinetic energy stored in the massive spinning turbines of traditional generators. This stored energy helps slow frequency changes, buying time for control systems to respond.

While LFC ensures stability, Economic Dispatch (ED) ensures efficiency. Once LFC determines the total generation needed, ED figures out which specific generators should provide that power to minimize overall operating costs.

ED algorithms consider the different costs of each power plant, from a low-cost hydroelectric dam to a more expensive natural gas plant. The goal is to allocate generator output to meet demand at the lowest possible total cost. This complex calculation must also account for transmission losses (power lost over long lines) and other system constraints, such as transmission line capacity, environmental regulations, and the ramp-rate limits of different generator types.

A well-tuned ED system can save millions in fuel costs, which helps stabilize electricity rates for consumers. While we at MTS Power Products typically work with backup generators, the same principles apply. Our power management solutions use intelligent controls to optimize fuel consumption and extend equipment life on a smaller scale.

Our power grids are evolving rapidly, driven by new technologies and the need for sustainable energy. This evolution brings both opportunities and significant challenges for automatic generator control.

The rise of distributed resources, bidirectional power flow, and smart grids introduces complexities that traditional AGC systems weren’t designed to handle.

The push for renewable energy like wind and solar is essential, but their variability poses a major challenge. Unlike predictable conventional power plants, renewable output depends on intermittent weather conditions. A sudden cloud cover or a drop in wind speed can create rapid imbalances that AGC must counteract.

This challenge is compounded by reduced system inertia. Traditional generators provide physical inertia with their spinning mass, which acts as a buffer against frequency swings. Inverter-based renewables lack this physical inertia, making the grid more susceptible to rapid frequency changes. To mitigate this, energy storage systems (ESS) like large-scale batteries are becoming critical. They can absorb excess energy or inject power when needed, acting as a fast-response buffer for AGC.

For a comprehensive look at how AGC is adapting, A review of control strategies for automatic generation control in power systems with renewable energy offers valuable insights.

To meet modern challenges, AGC systems are adopting more sophisticated control strategies beyond the classical methods.

| Control Strategy Category | Description | Key Characteristics |

|---|---|---|

| Classical Control | PID Controllers (Proportional-Integral-Derivative) are the workhorses. They calculate an error value (ACE) and apply corrections to generator output. | Simple, robust, widely used, but can struggle with non-linearities. |

| Modern Control | Model Predictive Control (MPC) uses a system model to predict future behavior and optimize control actions over a prediction horizon. | Handles constraints well, predictive, but computationally intensive. |

| Intelligent Control | Fuzzy Logic, Artificial Neural Networks (ANN), and Machine Learning (ML) learn from data and use human-like rules to manage complex, uncertain systems. | Adaptive, non-linear, can handle complex systems, requires training data. |

These advanced approaches are vital for managing the complexity of modern power systems. At MTS Power Products, we accept these innovations in our control panel designs and power management solutions.

With increasing digitalization, cybersecurity is a critical concern for automatic generator control systems. The communication networks that enable AGC are potential entry points for cyber attacks, which could lead to grid instability or widespread outages.

Maintaining data integrity is paramount. If sensor readings or control commands are manipulated, the AGC system could make incorrect decisions based on false information. As AI and machine learning are integrated, they also become targets for adversarial attacks designed to trick the models into making errors.

Robust cybersecurity measures, including encryption, authentication, and secure communication protocols like IEC 61850, are essential to protect these vital systems. As experts highlight, cybersecurity at the AGC level is crucial for national infrastructure. At our facility in Miami, we prioritize advanced security features in our control panels, because reliability today means both mechanical robustness and digital security.

An automatic generator control system is not a “set it and forget it” solution. Like a high-performance engine, it needs regular tune-ups to run smoothly and efficiently. AGC tuning is the process of evaluating and adjusting control parameters to ensure peak performance.

Performance evaluation centers on analyzing the Area Control Error (ACE). When ACE starts oscillating or drifting away from zero, it’s a clear warning sign. Ignoring it leads to higher costs, reduced efficiency, and potential compliance issues. At MTS Power Products, we know that proper control system performance is key to reliable power delivery.

How do you know it’s time for a tune-up? Look for these common signs:

With more than half of U.S. generating units over 30 years old, periodic tuning is more critical than ever.

Neglecting AGC tuning directly impacts your bottom line. A poorly tuned system leads to excess operational costs from inefficient dispatch and higher fuel consumption. It also causes increased unit wear and tear as generators constantly over-respond or oscillate, leading to more frequent maintenance and shorter equipment lifespans.

The good news is that tuning delivers a significant return on investment. For many power systems, conservative savings estimates are in the range of $100,000 per month after a proper tune-up. These savings come from improved fuel efficiency, reduced maintenance, and better market compliance.

In deregulated markets, a well-tuned AGC system helps avoid costly penalties for deviating from scheduled generation. The math is simple: regular tuning is an investment that pays for itself many times over by improving responsiveness, lowering costs, and extending equipment life.

Automatic generator control can be a technical topic. Here are answers to some of the most common questions we hear.

This is a common point of confusion. While both are “automatic,” they serve very different functions.

In short, AGC is about grid-wide production balance, while an ATS is about source switching for a specific location.

Yes, the core principles of stability and control absolutely apply. While formal AGC is for grids, a modern commercial backup generator uses its own sophisticated control system that mirrors the goals of AGC on a smaller scale.

Advanced generator control panels, like the McPherson Controls systems we design at MTS Power Products, continuously manage engine speed to maintain frequency, regulate voltage, and handle load changes smoothly. They monitor dozens of parameters to make instant adjustments, ensuring stable and safe power for your facility. This is especially critical for sensitive operations like data centers or hospitals. Your generator’s control panel acts as its own miniature AGC system.

Performance should be monitored continuously. For a comprehensive evaluation and tuning, the industry consensus is every 3 to 5 years. This accounts for the natural drift in equipment response and changing grid conditions.

However, you should conduct a tuning sooner if you make significant changes to your power system (like adding or retiring generators) or if you notice performance issues like control drift or oscillations. Given that much of the generating fleet is aging, staying on top of tuning is crucial for maintaining reliability and efficiency.

Automatic generator control is the unsung hero of our electrical world, working tirelessly to keep the grid stable and efficient. From balancing generation with demand every second to keeping costs down through Economic Dispatch, AGC is a remarkable system that most of us never think about—until the lights go out.

Today’s grids face new challenges from renewable energy, cyber threats, and aging equipment. Yet, the ingenuity behind modern AGC—from advanced controllers to machine learning—continues to meet these challenges head-on.

The principles of reliable power are universal. Whether managing a utility grid or protecting a single facility, reliable power depends on precise control. At MTS Power Products, we’ve built our reputation on this understanding. Our professional quality generators and advanced control panels embody the same commitment to precision and reliability that drives grid-scale AGC systems.

Our McPherson Controls line brings sophisticated control technology to commercial and residential applications, with features like remote monitoring and integrated safety mechanisms. Located minutes from Miami International Airport and the Port of Miami, we serve customers worldwide who demand the best in power quality.

Regular maintenance and tuning of control systems are not optional; they are an investment in continuity and efficiency. Future-proofing our energy infrastructure means embracing new technologies while maintaining the fundamentals of stability and reliability.

Ready to explore how professional-grade power control can protect your operations? Check out our selection of commercial backup generators designed to keep you running when it matters most.