Buy Direct

from the Manufacturer

Sell our Products

Become a Distributor

Discounts

on volume purchases

Visit Us

at our Miami office

from the Manufacturer

Become a Distributor

on volume purchases

at our Miami office

A generator voltage regulator is an electronic device that automatically maintains generator output voltage at a consistent level regardless of load changes or operating conditions. It’s the unsung hero of reliable power generation.

Quick Answer: Generator Voltage Regulator Function in 3 Steps

When your lights flicker during a storm or your business faces a power outage, the last thing you want is unstable power from your backup generator. Voltage fluctuations can damage sensitive electronics, reduce equipment lifespan, and even create safety hazards. This is where the voltage regulator steps in.

Think of a voltage regulator as the brain of your generator’s electrical system. Without it, your generator would produce wildly fluctuating voltage as loads change—much like a car without cruise control constantly speeding up and slowing down.

As Marathon Electric (serving customers since 1913) explains: “An automatic voltage regulator maintains generator output terminal voltage at a set value under varying loads and operating temperatures.”

Whether you’re a facilities manager like John looking to minimize downtime at your manufacturing plant, or a homeowner like Rebecca wanting reliable backup power during hurricane season in South Florida, understanding how voltage regulators work is essential for making informed decisions about your power generation needs.

Ever wondered what’s actually happening inside your generator when the lights stay bright even as your refrigerator kicks on? Let’s peek under the hood to see how a generator voltage regulator fits into the bigger picture.

Today’s generators are actually alternators that produce AC electricity through a fascinating process called electromagnetic induction. Think of it as a carefully choreographed dance between several key components:

The main stator sits motionless at the heart of your generator, producing the electricity that powers your home or business. Working in harmony with it is the rotor – the spinning assembly containing the main field winding that creates the magnetic field. The exciter acts like a mini-generator within your generator, providing the current needed by the rotor. And finally, the star of our show: the voltage regulator, which controls the exciter field to keep your output voltage steady.

“The generator produces voltage through electromagnetic induction,” explains one of our technical specialists at MTS Power Products. “Conductors moving through a magnetic field cut flux lines, inducing voltage.”

In simpler terms, your generator voltage regulator works like a dimmer switch for your generator’s magnetic field. Need more voltage? It strengthens the field. Too much voltage? It dials it back.

When shopping for a generator, you’ll encounter two main types of regulators:

| Feature | Analog Regulators | Digital Regulators |

|---|---|---|

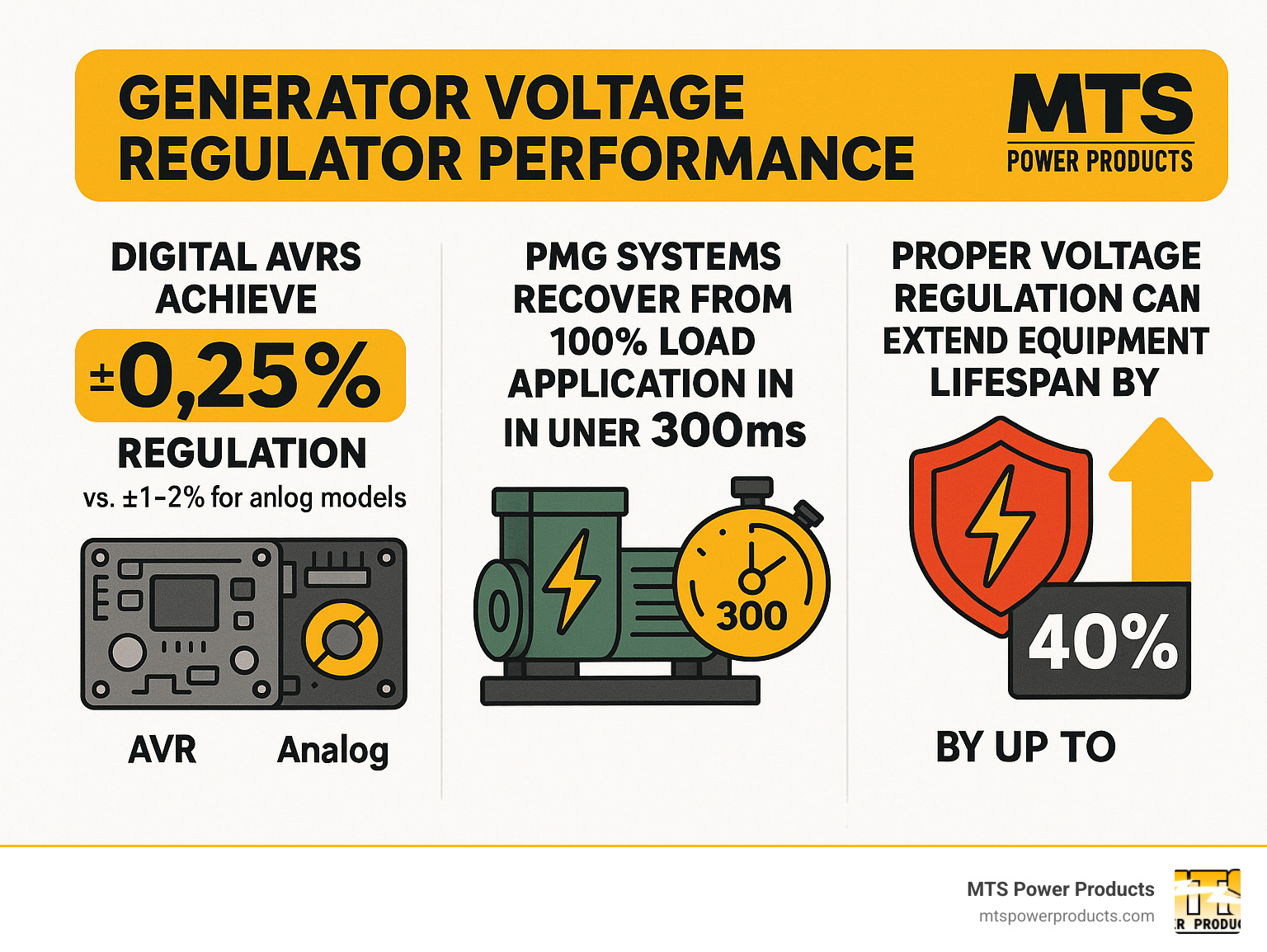

| Accuracy | ±1-2% regulation | ±0.25-0.5% regulation |

| Response Time | 10-20 milliseconds | <1-7 milliseconds |

| Features | Basic voltage control | Programmable protection, data logging |

| Cost | Lower initial investment | Higher initial cost, better long-term value |

| Reliability | Good, but subject to drift | Excellent, consistent performance |

If you have sensitive electronics or medical equipment, those digital numbers really matter. Our DVR® 2000E digital regulators, for instance, maintain voltage within an impressive ±0.25% from no-load to full-load using sophisticated RMS voltage sensing.

“Where’s Waldo?” might be easier than “Where’s my voltage regulator?” in some generators. The location varies based on your generator’s size and design, but there are three usual suspects:

For most mid-to-large commercial generators, you’ll find the generator voltage regulator tucked away in the generator control box – usually a separate enclosure with other control components.

Industrial generators often house their regulators in the alternator terminal box, where all the electrical connections come together.

If you have a smaller portable generator, peek under the alternator’s rear cover, and you’ll likely find your regulator hiding there.

“The voltage regulator placement and design vary with generator size,” our technical team at MTS Power Products often explains to customers. “Small units house the regulator in the generator end, while larger units use external designs for better access and cooling.”

This location matters when it’s time for maintenance or replacement. That’s why our McPherson Controls line features regulators designed for easy access – because nobody wants extended downtime when power is critical.

More info about voltage regulators in generators

A generator voltage regulator isn’t just another component – it’s your equipment’s bodyguard. Here’s why it matters so much:

Without proper regulation, your sensitive electronics would face a rollercoaster of voltage that could fry circuits or gradually damage components. Modern devices expect consistent power, and your regulator delivers exactly that.

Imagine your lights dimming every time your AC kicks on – that’s life without good voltage regulation. As load increases, voltage would naturally drop, causing motors to drag, lights to flicker, and electronics to behave erratically.

The safety implications are serious too. Overvoltage situations can create fire hazards, while undervoltage can cause equipment to draw too much current and overheat.

The precision of today’s regulators is remarkable – maintaining output within ±0.25% to ±2% of the target voltage even as demands change dramatically. For perspective, that’s like keeping your car within inches of the center line during a hurricane.

A data center manager in Miami recently shared with us: “After upgrading to MTS Power Products’ digital voltage regulators with ±0.5% regulation, we’ve eliminated the micro-outages that were plaguing our servers during generator testing.”

When you’re protecting mission-critical equipment or ensuring your family’s comfort during an outage, that level of precision isn’t just nice to have – it’s essential.

Scientific research on voltage stability

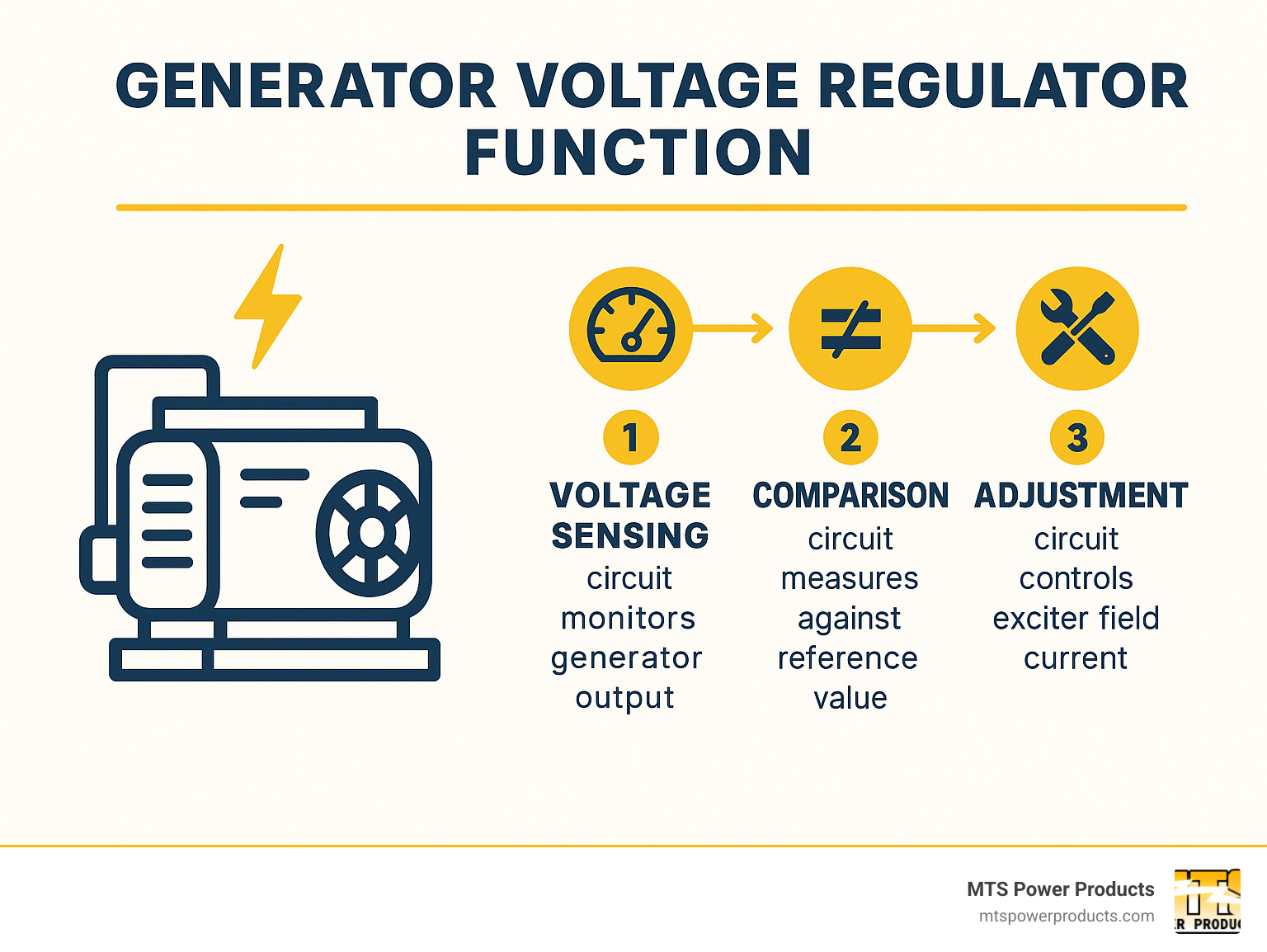

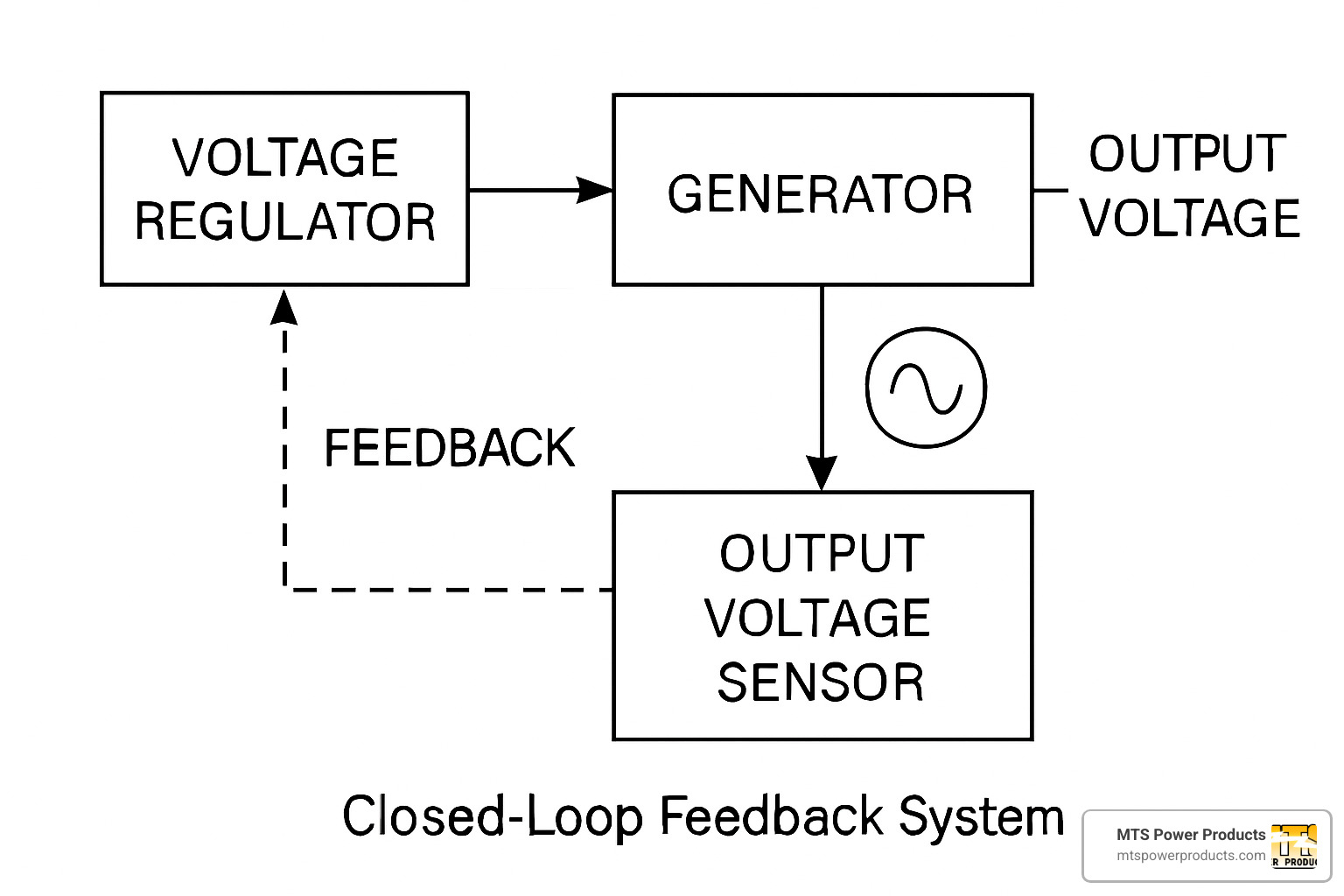

Now that you understand the components, let’s watch how a generator voltage regulator actually works in real-time. Think of it as a vigilant guardian that never takes a break – constantly monitoring, comparing, and adjusting to keep your power steady.

This continuous feedback loop happens many times per second – much like how your body automatically adjusts your breathing without you having to think about it. It’s an neat dance of electrical signals that keeps your power flowing smoothly.

Let me break down how a generator voltage regulator works in everyday terms:

Imagine you’re driving a car trying to maintain exactly 55 mph. You constantly check your speedometer (that’s voltage sensing), compare it to your target speed (reference comparison), and then decide if you need to press or ease off the gas pedal (error signal generation). When you adjust the gas pedal (field current adjustment), the engine produces more or less power (magnetic field change), which ultimately changes your car’s speed (output voltage correction).

Your generator’s voltage regulator does all this automatically – and does it in milliseconds! It’s constantly checking the output voltage through sensing leads, comparing it to what’s needed, and making tiny adjustments to the exciter field current to keep everything in perfect balance.

As one of our technicians at MTS Power Products likes to say, “The AVR is like a helicopter parent for your electricity – it never stops watching and adjusting to keep everything just right.”

When it comes to generator voltage regulators, you have three main options – each with its own personality and strengths:

Self-Excited AVR Systems are the simplest and most economical choice. They’re like the entry-level model that gets the job done under normal conditions. They draw power from the main stator output, which works fine when loads are stable. However, they can struggle during heavy motor starting or fault conditions – like trying to start your car with a weak battery.

Permanent Magnet Generator (PMG) Systems are the premium option. They use a separate small generator with permanent magnets to power the AVR independently. Think of them as having a dedicated backup power supply just for the voltage regulation system. This makes them exceptionally reliable even during tough situations like starting large motors or handling short circuits. For our customers running critical facilities in hurricane-prone Miami, this extra reliability is often worth the investment.

Auxiliary Winding Systems sit comfortably in the middle. They use a separate winding built into the main stator, offering better performance than self-excited systems without the full cost of a PMG. They’re like the “plus” model that gives you some premium features without the premium price tag.

We saw the difference these systems make during Hurricane Irma in 2017. Our Miami customers with PMG-equipped generators reported significantly better performance when starting air conditioners and water pumps during extended outages. One hospital facilities manager told us, “While other buildings struggled with voltage dips when starting essential equipment, our PMG system kept humming along like it was just another Tuesday.”

More info about how AVR works in generators

Now that you understand how a generator voltage regulator works, let’s talk about keeping it running at its best. Just like changing the oil in your car, regular maintenance keeps your power system reliable when you need it most.

Testing your generator voltage regulator isn’t complicated. With a simple multimeter and some basic safety precautions, you can check if your AVR is doing its job. Always start by turning off your generator and letting it cool down – safety first! Once it’s safe, locate your regulator, measure the AC input voltage, and check the DC output to the exciter field. When you run a test, watch to see if the voltage builds up and stabilizes at the correct value.

“The multimeter is your best friend when testing a voltage regulator,” says our lead technician at MTS Power Products. “It tells you immediately if something’s not right, often before you’d notice any problems with your lights or equipment.”

Industry experts recommend giving your generator voltage regulator a thorough check-up every 200 operating hours. This means looking for obvious problems like overheating or loose connections, cleaning off any dust (especially important in humid South Florida), and making sure all your settings are correct. Think of it as a regular health check-up – catching small issues before they become big problems.

Choosing the perfect generator voltage regulator for your generator is a bit like finding the right shoes – size matters, and comfort depends on the right fit. Your generator’s size (kW rating) should match your AVR’s capacity. The field current range needs to provide enough excitation power, and you’ll need to decide between single-phase or three-phase sensing options.

In South Florida’s challenging climate, environmental factors become especially important. Our McPherson Controls voltage regulators are specifically designed to handle Florida’s humidity and salt air, which can quickly damage standard components.

“I’ve seen standard regulators fail within months in Miami’s coastal environment,” explains our engineering manager. “Our regulators are built with this challenge in mind, using conformal coatings and corrosion-resistant materials that stand up to the elements.”

More info about automatic voltage regulators

Your generator voltage regulator will usually give you warning signs before it completely fails. Think of these as the “check engine” light for your generator system.

Flickering lights or unstable voltage readings are often the first sign something’s wrong. You might also notice your generator struggles when loads change, taking longer than usual to stabilize. If your generator runs but produces little or no voltage, that’s a clear red flag. Other warning signs include unusual heat from your AVR components, a burnt electronics smell, or your system triggering undervoltage or overvoltage alarms.

One of our Miami hospital clients recently shared a close call: “During our monthly test, we noticed the voltage jumping around more than usual. The MTS team diagnosed a failing AVR and replaced it before hurricane season hit. That quick action potentially saved us from a disaster during an actual emergency.”

Upgrading your generator voltage regulator can breathe new life into older generator systems. Modern digital regulators offer better accuracy than older analog models, and adding a PMG kit can dramatically improve performance during motor starting – crucial for air conditioning systems in Florida’s heat. Many newer regulators even offer remote monitoring capabilities, letting you keep an eye on your system from anywhere.

At MTS Power Products, we’ve helped countless South Florida businesses upgrade their power systems to handle the unique challenges of our region – from hurricane preparation to the everyday demands of our hot, humid climate.

Scientific research on failure impact

Ever wondered just how precise these little electronic marvels can be? Modern digital generator voltage regulators have come a long way from their predecessors. Today’s digital models maintain output voltage within an impressive ±0.25% to ±0.5% of the set value, even when loads are constantly changing. The older analog regulators typically manage ±1% to ±2% regulation—still respectable, but not quite as tight.

This might sound like splitting hairs, but that precision matters tremendously for sensitive equipment. One of our Miami data center clients put it perfectly: “The difference between ±2% and ±0.25% regulation might seem small, but for our servers, it’s the difference between stable operation and mysterious reboots during generator testing.”

Here at MTS Power Products, our McPherson Controls digital hybrid regulators deliver a solid ±0.5% regulation while standing up to Florida’s humidity, heat, and occasional salt air—something standard regulators weren’t designed to handle.

Absolutely! This is actually where modern generator voltage regulators really shine. Today’s AVRs include special features that make running multiple generators together smooth and reliable.

The key feature is called “droop mode,” which allows generators to share reactive load by slightly reducing voltage as reactive load increases. Think of it like teammates naturally adjusting their effort to carry a heavy load together. Some advanced models also offer cross-current compensation for even more precise load sharing, and the really sophisticated digital AVRs can maintain a specific power factor when running alongside utility power.

As one technical document puts it: “AVRs can divide reactive load between parallel generators using the voltage-droop principle.”

We’ve helped numerous commercial buildings in Miami configure multiple generators to run in parallel, providing both redundancy and increased capacity. Getting the AVR configuration right is absolutely essential for these systems to play nicely together.

Like any important piece of equipment, your generator voltage regulator needs regular attention to stay in top shape. Industry experts (and our own experience) suggest a simple schedule:

Look at it monthly during your regular generator tests—just a quick visual inspection to catch anything obvious. Then give it a more thorough check every 200 operating hours or at least once a year. The calibration should be verified annually or after you make any system changes. And finally, start thinking about replacement after 7-10 years, or sooner if you notice signs of trouble.

As one maintenance guide states: “A comprehensive inspection and maintenance should be performed every 200 hours of operation.”

Here’s an insider tip from our team at MTS Power Products: If your generator is near the coast in South Florida, consider more frequent inspections. The combination of humidity and salt air can accelerate wear on electronic components—something we’ve learned from years of serving customers from Miami Beach to the Keys.

We’ve designed our maintenance programs specifically with South Florida’s challenging environment in mind, helping your equipment last longer even when Mother Nature isn’t being particularly cooperative.

Let’s wrap this up in a way that makes sense. After reading through our guide, you’ve taken a journey from curious to confident about generator voltage regulators. The three steps we’ve covered give you a practical understanding that you can actually use:

Living in South Florida means preparing for hurricane season is just part of life. At MTS Power Products, we’ve helped countless customers through power emergencies when they needed reliable backup power the most. Our experience with Florida’s unique challenges—humidity, salt air, and those summer storms—has shaped how we approach generator systems.

Our McPherson Controls voltage regulators aren’t just technically advanced; they’re built to withstand the specific challenges our region throws at them. Whether you’re protecting medical equipment at a healthcare facility, keeping servers running at a data center, or just making sure your home stays powered during the next big storm, proper voltage regulation isn’t a luxury—it’s essential.

Think of your voltage regulator as the unsung hero of your power system. When it’s working correctly, you don’t even notice it. But when something goes wrong, the consequences can range from annoying flickering lights to damaged equipment that costs thousands to replace.

We’re conveniently located just minutes from Miami International Airport and the Port of Miami, making us perfectly positioned to serve South Florida quickly while still offering worldwide shipping capabilities. Don’t wait until the weather forecast turns ominous—reach out today and let us help you assess your power generation system before you actually need to rely on it.

More info about Generator Voltage Regulator solutions